Thermal breaks prevent heat loss

by Brent Chancellor, PhD, P.Eng.

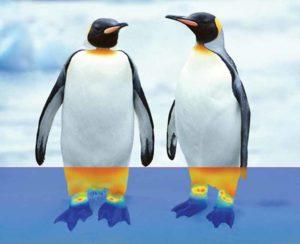

Emperor penguins can survive Antarctica’s frigid climate because—much like efficient building envelopes—their bodies contain an air and moisture barrier, continuous insulation (ci), and thermal breaks preventing heat loss into the environment.

Air and moisture barrier seals out weather

The only animal to inhabit the open ice of Antarctica during the winter, emperor penguins withstand wind chills of up to –60 C (–76 F) and blizzards up to 200 km/h (124 mph). Scale-like feathers shield their bodies from harsh wind, ice, snow, and water, while their skin provides the final barrier to transmission of moisture and vapour.

Similarly, modern building envelopes prevent the migration of moisture from the outside environment to the inside. Some envelopes employ a combined moisture/air barrier, while others utilize a rainscreen.

Continuous insulation retains heat, conserves energy

The emperor penguin’s thick layer of continuous blubber serves as its primary insulation against bitter temperatures. Additional insulation is provided by its feathers, which trap a layer of air against the skin.

While the penguin’s ci is dictated by natural selection, the ci of commercial building envelopes is now being dictated by code requirements. Many provincial and local codes already require structural thermal breaks (STBs) when taking a prescriptive path, and others are not far behind in the adoption of more stringent standards.

Thermal breaks prevent heat loss into the environment

Emperor penguins prevent the escape of heat through their feet into the ice and water by means of thermal breaks in their legs: a vascular adaptation thermally separates their rounded, well-insulated bodies (low surface-area-to-volume ratio) from their flat, poorly insulated feet (high surface area-to-volume ratio).

Similarly, the balconies of commercial buildings—cantilevered structural extensions of commercial building floor slabs—quickly equalize to cold exterior temperatures. As a result, balconies continuously transfer heat from the interior floor slab to the exterior environment, unless thermal breaks are installed where the balcony interrupts the ci of the building envelope.

Traditional balcony construction wastes heat

Conventional concrete and steel balconies are designed as cantilevered extensions of steel or concrete floor slabs because of loadbearing requirements. Thus, they not only create a thermal bridge in the ci of the building envelope, but also rapidly conduct heat from the interior slab through the cantilevered balcony and into the environment.

Prior to 2010, wasted heat and cold interior floors were accepted as unavoidable outcomes in North American buildings with balconies. Problems of mould growth arose when builders began wrapping exteriors with airtight vapour barriers.

Before airtight envelopes, most commercial buildings leaked air profusely, causing humidity levels inside buildings to equalize with low exterior humidity levels during winter months. Forced hot air (typically vented at or near balcony doors and windows) further ensured interior humidity remained too low at the cold balcony penetration to reach dewpoint, form condensation, or support mould growth.

However, as mentioned, the advent of airtight vapour barriers to prevent leakage of heated air during the late 20th century had a major unintended consequence: increased mould growth.

As a building becomes more airtight, it requires less heat and retains more moisture from evaporation and human off-gassing. This can increase interior humidity by 35 to 40 per cent—the target level for human comfort, which can also create a danger zone for condensation when the thermal conductivity of balconies drops the temperature to the dewpoint on the interior side of the envelope at the point of penetration.

With nowhere to go, the moisture will condense if interior temperatures drop to the dewpoint, especially within cold wall cavities adjacent to uninsulated balconies and other envelope penetrations. The resulting condensation leads increasingly to mould growth on gypsum board, studs, and insulation on the inside of the building. Mould can grow and cause respiratory problems in building occupants years before it becomes visible on interior ceilings and walls.

By then, remediation will, at minimum, require removal and replacement of gypsum board. However, mould is likely to recur since high interior humidity and cold envelope penetrations in existing structures are unlikely to be corrected due to difficulty and cost.