The Theory of R-value Relativity: The impact of thermal conductivity on building enclosure durability

Going forward

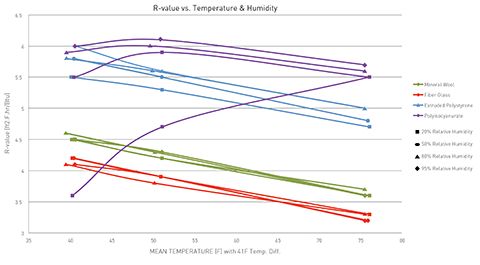

It is important to remember using static R-values and static temperatures to calculate dewpoints (through the Glaser method) can be helpful in tight situations. However, the potential result may include unexpected heat loss, durability issues, and mould issues (due to underestimating condensation hours). (The Glaser method is a simple calculation model to help assist design professionals in determining the dewpoint (condensation) within their enclosure designs. Calculations are based on static R-values, temperatures, relative humidity (RH), and permeance.)

Bulk water formed or directed in the building assembly does not always result in deterioration, provided stipulations are introduced in the system to account for deficiencies. Various provisions to minimize the potential for moisture damage, such as the specification of materials, also allow for continuous drying. Additionally, the location of materials to force dewpoint outboard of control layers is important, as well as adequate drawing and site review.

In addition to industry-standard testing, product manufacturers must be held more accountable to demonstrate how their products/systems perform in-situ. As for insulation, a building owner essentially purchases R-value, therefore, it is important to get the full value of the product.

The fundamental understanding of how the industry works and calculates R-value has to change. It has been documented that not all insulations are created equal; if treated as such, this can lead to durability issues as well as increased energy use. To ensure the enclosure is designed as intended, it is imperative all factors are taken into account. Designers should not hesitate to ask manufacturers the tough questions, since it is their name on the construction documents.

Rockford Boyer, B. Arch. Sc., BBSO is the North American manager of the Energy Design Centre for ROXUL Inc. (Milton, Ont.) Rockford has been with the company for more than eight years, serving in the technical innovation department. Previously, he was a building science specialist with AMEC Earth and Environmental. He has a diploma in civil engineering, a degree in architecture (building science), and is currently in the process of completing his master’s degree in building science. Boyer can be reached at rockford.boyer@roxul.com.

Rockford Boyer, B. Arch. Sc., BBSO is the North American manager of the Energy Design Centre for ROXUL Inc. (Milton, Ont.) Rockford has been with the company for more than eight years, serving in the technical innovation department. Previously, he was a building science specialist with AMEC Earth and Environmental. He has a diploma in civil engineering, a degree in architecture (building science), and is currently in the process of completing his master’s degree in building science. Boyer can be reached at rockford.boyer@roxul.com.