The Well in downtown Toronto

by Alison Knight

Image courtesy RioCan REIT and Allied Properties REIT

In a city where construction is constant, developers are looking for opportunities to incorporate green energy solutions into their projects. Case in point: The Well project in Toronto.

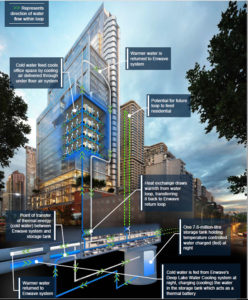

This new addition to Toronto’s downtown core will feature seven towers of mixed-use space housing 102,193 m2 (1.1 million sf) of retail and food service space, 46,451 m2 (500,000 sf) of office space, and nearly 2000 residential units, all sitting atop a new thermal energy facility.

In a hole reaching 43 m (140 ft) below the lowest level of the construction site, one 7.6 million L (2 million gal) tank will store temperature-controlled water fed by an existing deep lake water cooling (DLWC) system. A new high-efficiency hot water network will also take advantage of the storage onsite. This facility will allow for energy to be stored during off-peak demand times, so that it can be deployed to customers when needed.

“We are building as big a tank as we possibly can under the constraints of the site,” says James Scharbach, Enwave Energy Corporation’s project manager for the Well. “No one has put a giant hole in the ground underneath a huge active construction site like we are doing in this project. It is innovative, complicated, and many creative minds are working together to make the design and construction process a success.”

How it works: Cooling

Image courtesy Enwave Energy Corporation, RioCan REIT, and Allied Properties REIT

To charge the tank, chilled water comes in from Enwave’s DLWC system and cools down the thermal storage water loop to 5.5 C (42 F) through a heat exchanger. Then onsite chillers utilize a supercooling solution in the loop to drive down the temperature below the freezing point. This water is injected slowly into the bottom of the thermal storage tank using a specially designed diffuser system to ensure warm and cold water do not mix and the narrow thermocline is maintained. Meanwhile, the warmer water is removed from the top of the tank and brought back to pick up rejected heat from the chiller, which is created through the chilling process. This eliminates the need for cooling towers. Finally, this warmer water is brought back again to the DLWC heat exchanger and cooled back down to 5.5 C, and the process begins again.

In the discharging process, water is taken from the bottom of the tank where the cool water is at its most dense, and the charging process is reversed. Through the same heat exchanger used to charge the tank, this water now provides cooling for the buildings at the Well and for export to the district cooling system. The resulting warm water is then injected back into the top of the tank.

Heating

Charging the tank for heating purposes is similar to the cooling process, as hot water from the district system is used to heat the thermal storage loop. Water as hot as 82 C (180 F) is injected into the top of the tank, while cooler water is removed from the bottom. To discharge, the less dense hot water is pulled from the top of the tank and sent to the district heat exchangers. Hot water is then exported to the district hot water loop to heat customer buildings after heating those at the Well.

The site will not only provide the Well community with sustainable heating and cooling solutions, but also serve as an anchor to the west side of Toronto. This new energy hub will be central in expanding the existing system to make it capable of delivering resilient, low-carbon heating and cooling to more than 1.8 million m2 (20 million sf) of commercial, retail, and residential space.