Designing With Stainless Steel: Bioclimatic hybrid façades

Photo courtesy Ronstan Tensile Architecture

On the building’s north side, which receives the most sun, passive green plant screens were used on the sides of balconies (Figure 3). They are supported by a Type 316 mesh and tension cable system and there are planters on each floor. The 1-m (3-ft) balcony projections shield windows from high-angle sun, and the green screens along their sides screen low-angle sun, filter glare, and connect occupants with their environment while providing privacy.

The vegetated screen extends upward to the roof and provides an arbour-like sunshade for the rooftop terrace. Like a vegetated roof, the natural green plant screen shelters the roof from the sun. The fully usable, attractive, shaded recycled wood roof deck also has a rock garden with living green sculptures supported by Type 316 mesh.

The success of vegetated building and landscaping privacy and sheltering screens depends on selection of appropriate vines for the region and maintenance pruning to encourage vine spread. Therefore, if service life is not limited, it is critical to use a supporting structure not reliant on coatings for corrosion resistance, as these cannot be reapplied without damaging the screen.

Corrosive coastal or de-icing salts and pollutants may accumulate on surfaces, and even natural fertilizers can be corrosive. Additionally, no part of the supporting structure should release chemicals or metals that kill plants (e.g. biocides), and its strength should not deteriorate over time with ultraviolet (UV) exposure, as will occur with plastics.

A high level of strength is necessary for these lightweight airy structures to withstand higher wind loads when fully vegetated. For these reasons, stainless steel is the logical choice for long-term installation. These screens naturally adjust to the seasons allowing more winter light to enter buildings.

Champlain port of entry

The border crossing between Champlain, N.Y., and Saint-Bernard-de-Lacolle, Que., is one of the five busiest between Canada and the United States, and the most important for Québec. A new building and gateway was completed for the U.S. port of entry’s land side in March 2010. The project team consisted of Smith-Miller + Hawkinson Architects LLP (New York City), and contractor Northland Associates Ltd. (Liverpool, N.Y.).

Photo courtesy Cambridge Architectural

Type 316 woven stainless steel, and the structural support system for it, was used for signage above the primary inspection booths, and as a sunshade system on the cargo processing facility’s exterior. The screen significantly reduces solar glare, light pollution, and solar heat gain. Unlike conventional shading materials, architectural mesh also promotes airflow and enhances building security; it is also designed to meet an array of opacity, shading, and heat reduction requirements (Figure 4).

Transformative passive screens

Unlike tensile supported systems that parallel the insulated wall, lightweight framing supports for woven mesh or perforated panels allow the distance between the inner insulated skin and exterior hybrid second skin to vary, making seamless curving, geometric, and other shapes possible. This flexibility can dramatically change a new or existing building’s appearance at a much lower cost than installing an undulating insulated curtain wall.

Photos courtesy Iwan Baan Studio

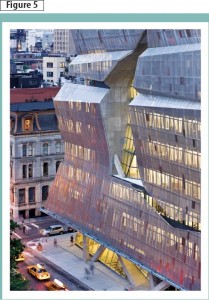

41 Cooper Square

41 Cooper Square, a new building at The Cooper Union, designed by Morphosis Architects, is the first U.S. Green Building Council (USGBC) Leadership in Energy and Environmental Design (LEED)-certified educational building in New York City (Figure 5). This 16,258-m2 (175,000-sf) multi-award winning project received a Platinum rating for its innovative design.

The operable double-skin design uses Type 316 stainless steel perforated panels offset from a glass and aluminum window wall. This semi-transparent layer wraps around a traditional building shape, giving it a dramatic sculptural presence with areas of light and shadow. The perforated panels reduce heat radiation in the summer, shelter and insulate the inner wall in winter, and allow natural light to enter.

When the sculptured curving second skin was combined with natural ventilation, a vegetated roof, and radiant heating and cooling ceiling panels, it was possible to reduce the building’s energy requirements by 40 per cent relative to a standard building of its type. A full-height atrium improves air circulation and provides additional indoor lighting. About 75 per cent of the building’s regularly used interior spaces are lit with natural light.

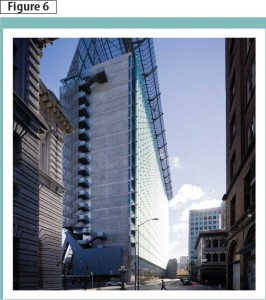

San Francisco Federal Building

The San Francisco Federal Building, built in 2007, and also designed by Morphosis, is a slender 56,205-m2 (605,000-sf) 18-storey tower connected to a four-storey annex and adjoining a public plaza (Figure 6). The use of sunscreens on both the building and adjoining plaza make a visual connection between them. The structure was the first office tower in the United States to give preference to natural ventilation––about 70 per cent of the work area is naturally ventilated rather than air-conditioned. The narrow tower design also means 90 per cent of the workstations have natural lighting and operable windows.

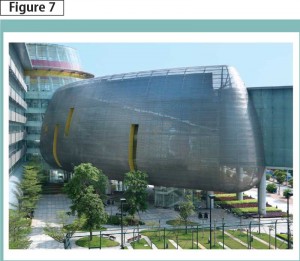

The folded, perforated Type 316 stainless steel sunscreens cover full-height glass window walls, shielding them from heat gain, sheltering them from inclement weather, and allowing natural light into the building. The computer-controlled mutable skin adjusts to daily and seasonal climate fluctuations. The building surpasses the U.S. General Services Administration’s (GSA’s) energy performance criteria by 50 per cent and sets new standards for passive climate control. (See “Morphosis and Arup Engineers Create Dynamic Form that Follows Function for the U.S. Federal Building in San Francisco,” by Joann Gonchar in the August 2007 issue of Architectural Record). Guangzhou 2nd Children’s Activity Centre Completed in 2006, Guangzhou 2nd Children’s Activity Centre (China) provides teaching, performance, and exhibition space for after school and weekend arts-education courses for primary and secondary school students (Figure 7). Designed by Steffian Bradley Architects (SBA), this 42,735-m2 (460,000-sf) concrete building has a capacity for 20,000 people. The dramatic and seamless compound curves on the exterior were made possible by the use of a Type 316 stainless steel mesh metal panel system. Site orientation and green spaces maximize sustainability by capitalizing on shading, daylight, and wind.

The building is set on one storey of columns so the outdoor plaza continues beneath the building, which retains open circulation at street level and allows pedestrians to enjoy the natural surroundings. The arrangement of building elements relative to the prevailing wind directions and the open ground and upper floors allows for natural ventilation, eliminating the need for air-conditioning in common spaces. The mesh also hides the HVAC units. The strategic placement of a curved element against a linear element is intended to maximize natural light exposure and minimize shadow line coverage, while creating a distinctive identity and enhancing energy savings and sustainability.

Photo courtesy Steffian Bradley Architects

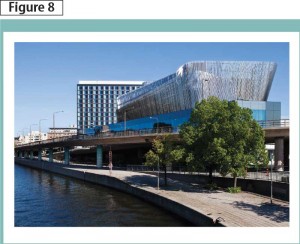

Stockholm Congress Centre

Sweden’s new Stockholm Waterfront, a congress centre located along the waterfront in the heart of the city, is a layered structure designed for significant energy reduction. Contoured, ribbon-like, softly reflective pieces of stainless steel hover away from the structure, creating its distinctive, undulating appearance.

Long service life, low-maintenance materials were necessary for the sunscreen, which angles outward from the wall. It used 3500 Z-shaped duplex 2205 stainless steel sections, 3 to 16 m (9.8 to 52.5 ft) in length. The sunscreen has a semi-reflective matte finish. The screen angle reflects away summer sun while allowing natural light to enter. The seasonal angle of the sun changes––in winter, sunlight passes through the wall to passively heat the building.

Although Stockholm does not have a severe coastal environment, sections of the sunscreens are sheltered from rain. The architect, White Arkitekter of Stockholm, obtained advice from the stainless steel producer and specified the more corrosion-resistant, higher-strength duplex stainless steel 2205 (Figure 8). Completed in early 2011, the building is expected to receive green building certification.

Photo courtesy Outokumpu

Conclusion

Successful sustainable bioclimatic design requires material selection that can last the structure’s life. Site analysis should consider exposure to pollution, corrosive salts, and the likelihood of manual or rain cleaning when conducting a lifecycle analysis. Stainless steel is the most corrosion-resistant of the readily available architectural metal options and, therefore, is being used for applications ranging from sunscreens to landscaping.

When an appropriate stainless steel alloy and finish are specified, it will provide attractive performance over the building’s life, and has no toxic runoff that might harm the environment. Stainless steel has a recycled content of at least 60 per cent, and 92 per cent of the stainless steel used in architecture is reused to make new material. For these reasons, stainless steel is an ideal choice for sustainable architecture.

Bioclimatic design concepts can have a substantial impact on the sustainability and comfort of Canadian buildings in temperate and cold climates. The Stockholm Congress Centre and German corporate campus projects mirror concepts being used in Canada, including taking advantage of the seasonal angles of the changing sun and using second-skin façades to shelter windows from winter weather. As designers become more familiar with the design concepts and benefits of second-skin bioclimatic façades, their use in Canada will continue to grow.

Catherine Houska, CSI, is a senior development manager at TMR Consulting. She is a metallurgical engineering consultant specializing in architectural metal specification, restoration, and failure analysis. Houska has authored more than 128 publications, including several features for Construction Canada and The Construction Specifier. She can be reached via e-mail at chouska@tmr-inc.com.