Beyond RSI-value: Canada’s carbon shift in construction

This year, the author attended two national conferences focusing on resource reduction and sustainable building practices. The first was the 2025 Canadian Circular Economy Summit in Montreal and the second was the 2025 Passive House Canada Conference in Ottawa. Although the two conferences focused on two different topics, one focused on resource reduction, resource recycling, and resource recovery, and the other focused on sustainable building practices to reduce material use, and energy consumption—the underlying theme of these conferences was the reduction of carbon and minimizing the impact of climate change due to excessive material and energy use. Discussions on carbon have been circulating around certain circles in the industry; however, carbon and its impact on buildings and the environment will be at the forefront for years to come. There has also been some interest from the Canadian Board for Harmonized Construction Codes (CBHCC) who emailed looking for input on embodied greenhouse gas emissions in the National Model Codes.

CO2 and its impact

More recently, in St. John’s, at the Construction Specifications Canada (CSC) 2025 National Conference, there was a discussion on carbon and its impact on the construction industry. The question posed to the architects and specifiers was, “Do you see designers and specifiers using embodied carbon as a medium for choosing building materials?” The answer was an enthusiastic yes. There are efforts to currently integrate low-carbon material solutions into designs and specifications. It is great to see the industry innovating and incorporating climate change reduction practices prior to it becoming the norm. To help with the progression of low-carbon solutions in the built environment, this article will discuss what carbon is and how building materials, more specifically thermal insulating materials, impact climate change.

Fifteen years ago, when the word “carbon” was heard in Canada, everyone associated the word carbon with “stick.” For example, if the Toronto Maple Leafs did not use those carbon fibre sticks that break all the time, they would win the Stanley Cup (here’s hoping this will happen soon). Fast forward to now, when the word carbon serves as a reminder that the reduction of carbon is needed to reduce the impacts of climate change and severe weather events. Canada’s global carbon impact is only 1.6 per cent, however, reducing net carbon impact is key. More importantly, Canada must be seen as a global leader in low-carbon built and operational buildings.

When the term “carbon” is used, it is generally referring to “carbon dioxide” or its chemical formula name CO2. Carbon dioxide is an odourless gas typically created from the burning of fossil fuels and is the primary cause of climate change. It impacts climate change by absorbing infrared radiation and holding the radiation for hundreds of years, essentially creating a blanket around the atmosphere and keeping the heat in (greenhouse effect). Almost 100 per cent of the carbon created by humans goes directly to the atmosphere, except for the one per cent that can be recovered. CO2 is needed for life on Earth, however, there must be a defined balance of absorption (plants) and creation (burning of fossil fuels). Canada has more than 318 billion trees within its borders, and each mature tree absorbs 25 kg (56 lb) of CO2 per year. Deforestation and forest fires can significantly decrease the amount of CO2 absorbed by the nation’s forests; therefore, other precautions must be taken to reduce the CO2 creation, especially by the construction industry.

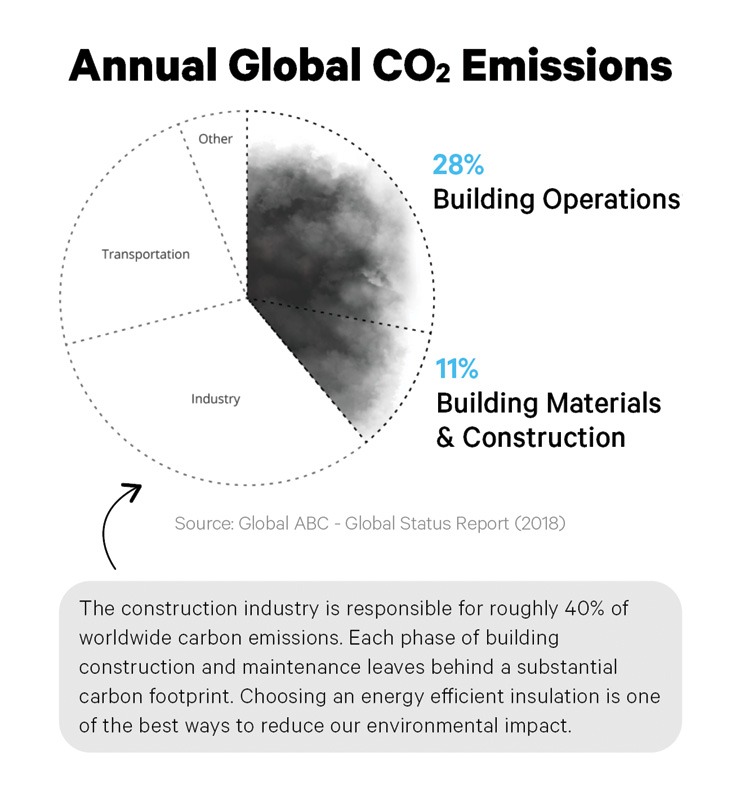

The construction industry accounts for approximately 40 per cent of the total global CO2 emissions on an annual basis. The impact can be separated into two distinct carbon contribution paths, the first being from the building materials/construction and the second from the operation/maintenance of the building.

Embodied carbon from the building materials and the construction practices accounts for approximately 11 per cent of the total emissions, whereas the operation of the building accounts for approximately 28 per cent of the total CO2 emissions. Industry, transportation, and other account for the remaining 61 per cent of the total global emissions. When narrowing down both the embodied carbon and operational carbon of buildings, thermal insulation has a significant impact on both paths of total annual carbon creation. Using low carbon thermal insulations and using these insulations effectively can significantly decrease the CO2 developed from inefficient building operation.

Thermal insulation and sprayfoam

The author has been in the insulation industry for 20 years (this is one-third of the time since the Toronto Maple Leafs won the Stanley Cup). In those 20 years, there have been major differences between the types of thermal insulations and how they are manufactured. There are two ways to manufacture traditional thermal insulation, the first method uses fossil fuels (e.g. natural gas, electricity, coke) to melt rock/sand/glass and spin them into fibres. The second method is to blend various raw materials with a blowing agent to create a foam-based insulation. These products can be either manufactured in a stationary manufacturing plant (board stock) or can be manufactured onsite by a certified professional (sprayfoam). Both types of thermal insulations provide value for the project; however, their embodied carbon and inherent product properties can dictate the enclosure performance and carbon impact.

Manufacturing thermal insulation as mentioned above can differ substantially, therefore reviewing a product Environmental Product Declaration (EPD) can assist in choosing a product that will have the least amount of site-specific environmental impact. Reviewing the thermal insulations performance qualities will also ensure any inefficiency or redundancy is avoided. A total enclosure carbon footprint should be calculated in its entirety instead of its individual components. An example of this is a closed-cell sprayfoam, which can be a thermal insulation, air barrier, moisture barrier, and vapour barrier; whereas fibrous insulation is typically a thermal insulation only and a secondary membrane is required to control the air, vapour, and moisture. Research and case studies have started to appear demonstrating the total carbon footprint of the overall wall enclosure and not just the embodied carbon of thermal insulation.

EPDs are valuable third-party verified tools which can assist in determining how much CO2 was created from the extraction, manufacturing, transportation, and disposal of the product in question. Results from the EPDs are derived from the data obtained by the life-cycle analysis (LCA) and can assist the designer or stakeholders in making informed decisions on the products used in their buildings. Typically, manufacturers have their specific EPDs for the products they manufacture; however, industry organizations such as Spray Polyurethane Foam Alliance (SPFA) or North America Insulation Manufacturers Association (NAIMA) have conducted industry-wide EPDs for their members. As previously stated, these EPDs are for thermal insulations only; looking at the total embodied carbon footprint of the enclosure is needed to understand the full dynamics of the calculation. These calculations will include the cladding, insulation, structural components, air/vapour/moisture barriers, minor structural components, finishes, etc.

Resources

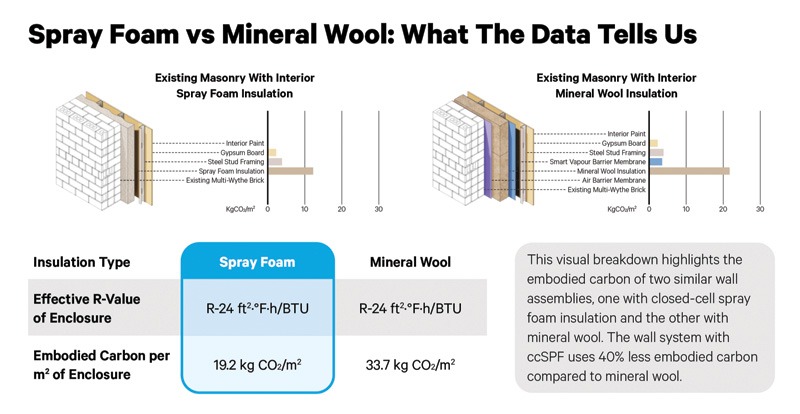

A new design resource from RDH Building Science, Toronto Metropolitan University (TMU), and The Atmospheric Fund is helping designers better understand the carbon impact of building assemblies. Titled “New Design Resources for Embodied Carbon Targets,” the guide evaluates the embodied carbon footprint of 26 different wall, roof, and floor assemblies using a consistent methodology. The aim is to provide architects, engineers, and specifiers with practical, material-specific data to support low-carbon design decisions early in the process. What sets this guide apart is its detailed breakdown of each assembly, showing the contribution of individual materials such as insulation, sheathing, structure, and cladding to the overall embodied carbon total. The scope of the study includes carbon generated from raw material extraction through to the building’s use phase, offering a clear picture of carbon impacts up to occupancy. While end-of-life considerations are not included, the data still represents a major step forward in transparency and comparability for enclosure design.

This type of resource is especially timely as more design teams begin integrating embodied carbon targets into their project goals. Understanding how each component contributes to a wall or roof’s overall footprint allows for more informed substitutions and optimization without compromising performance. A sample wall assembly from the guide is shown in Figure 1 for reference. For those interested in diving deeper, the full set of assemblies and carbon data is freely available on the RDH Building Science website.1

The intent was to demonstrate the carbon impact of upgrading two existing masonry wall assemblies with an R-24 solution with either a closed-cell spray polyurethane foam (ccSPF) or mineral wool type of insulation. For the ccSPF retrofit, 102-mm (4-in.) steel studs were installed on the interior face of the masonry, filled with 95-mm (3.75-in.) of ccSPF. The assembly was completed with a standard gypsum finish and interior paint. However, the mineral wool option required a few additional layers. Since mineral wool is strictly thermal insulation and does not manage air, vapour, or moisture movement, additional control layers had to be added. The assembly included a continuous air barrier applied to the brick, 152-mm (6-in.) steel studs, 152-mm (6-in.) of mineral wool insulation, a smart vapour retarder, plus the standard gypsum and paint finish.

This is where the carbon story gets interesting. Despite mineral wool often being seen as the “greener” option, this assembly had a higher embodied carbon impact. The ccSPF assembly resulted in approximately 40 per cent less embodied carbon compared to the mineral wool version. Why? Fewer materials, fewer layers, thinner structural elements and integrated performance. The example from the guide is a good reminder that reducing carbon in an assembly is not just about the insulation type, but how all the components come together in the full assembly to control the four layers of performance. It should be stated that even though some insulation types can have higher embodied carbon, they do minimize the impact of energy use in the operation of our buildings. The higher carbon insulation types, such as mineral wool (higher density equals higher carbon), will be a net carbon benefit; however, it may take a longer return on carbon (ROC).

Additional work is already underway to build on the Embodied Carbon Resource guide. RDH Building Science, along with industry partners, are digging deeper into the carbon side of enclosure design to give the architectural and specifier community better tools to make informed, performance-based decisions. While EPDs are a solid starting point, they offer verified data on material-level embodied carbon; they do not give us the full picture.

The reality is, no single product defines the carbon story of an assembly. To truly understand a building enclosure’s impact, every component, cladding, sheathing, structure, insulation, membranes, and finishes need to be broken down and labelled with their embodied carbon value. Only then can people see how each piece contributes to the overall carbon footprint of the enclosure.

This level of transparency will move the industry from theoretical carbon targets to real, design-based decisions. Once working with full-enclosure data, the industry will be in a better position to rethink how walls, roofs, and floors are detailed and specified, not just for thermal performance or durability but also for long-term climate impact.

Conclusion

In recent months, carbon reduction has dominated the conversation across industry events, from the Canadian Circular Economy Summit in Montreal to the Passive House Canada Conference in Ottawa. While the discussion varied from materials reuse to energy efficiency, the common thread was clear: carbon matters, and the building enclosures are a key part of the solution. Thermal insulation plays a central role here, influencing both embodied and operational carbon.

While Canada’s global carbon share sits at 1.6 per cent, its reputation as a global leader in climate resilience depends on lowering that footprint, starting with how buildings are designed and built.

Material choice matters, but how materials work together matters more. While EPDs are a solid starting point, they do not tell the whole carbon story—full enclosure assessment is where meaningful change happens. The ongoing research by RDH, Honeywell, and Elastochem aims to expand these tools and bring more clarity to designers and specifiers. Until then, the industry needs to be asking the right questions: not just “what’s the RSI-value?” but “what is the carbon cost and is there a smarter way to get the same performance?”

Let’s get the buildings to net-carbon zero before the Toronto Maple Leafs have a chance to win the Stanley Cup, or maybe let’s not wait that long.

Notes

1 Refer.

Author

Rockford Boyer, B. Arch. Sc., MBSc, BSS, is an experienced building science leader at Elastochem with more than 20 years of expertise in sustainable building design. He holds an undergraduate degree in civil engineering and architecture and a master’s in building science. He is also a member of Passive House Canada and the Ontario Building Envelope Council (OBEC). He is also a part-time professor at Sheridan College, teaching in the architectural technology program and sharing his knowledge and expertise with future generations of architects and designers.