Next-gen insulation and its impact on the built industry

Ming Xie, vice-president of research and development at Kingspan Insulation North America, spoke to Tanya Martins, online editor at Construction Canada, about the next generation of insulation and why it is crucial for the future of the built industry.

When evaluating the performance of new insulation material, critical performance parameters are thermal conductivity, compressive strength, water absorption, fire performance, corrosivity, and VOC.

How are emerging insulation technologies addressing both thermal performance and sustainability?

Emerging insulation technologies should have better thermal performance than conventional products. For example, vacuum-insulated panel technology has started to gain traction as a viable insulation material globally. These products offer much better thermal performance. Other emerging technologies, such as aerogels and phenolic, have superior thermal performance as well as fire performance.

Sustainability performance of insulation materials has increasingly become an important factor specifiers investigate. Hemp and wood fibre-based materials are making their entry into the U.S. market. These materials are built on their sustainability benefits while offering comparable thermal performance to traditional materials such as fibreglass and mineral wool, while offering much better global warming potential (GWP).

What role does advanced insulation play in meeting new or upcoming building codes and climate targets?

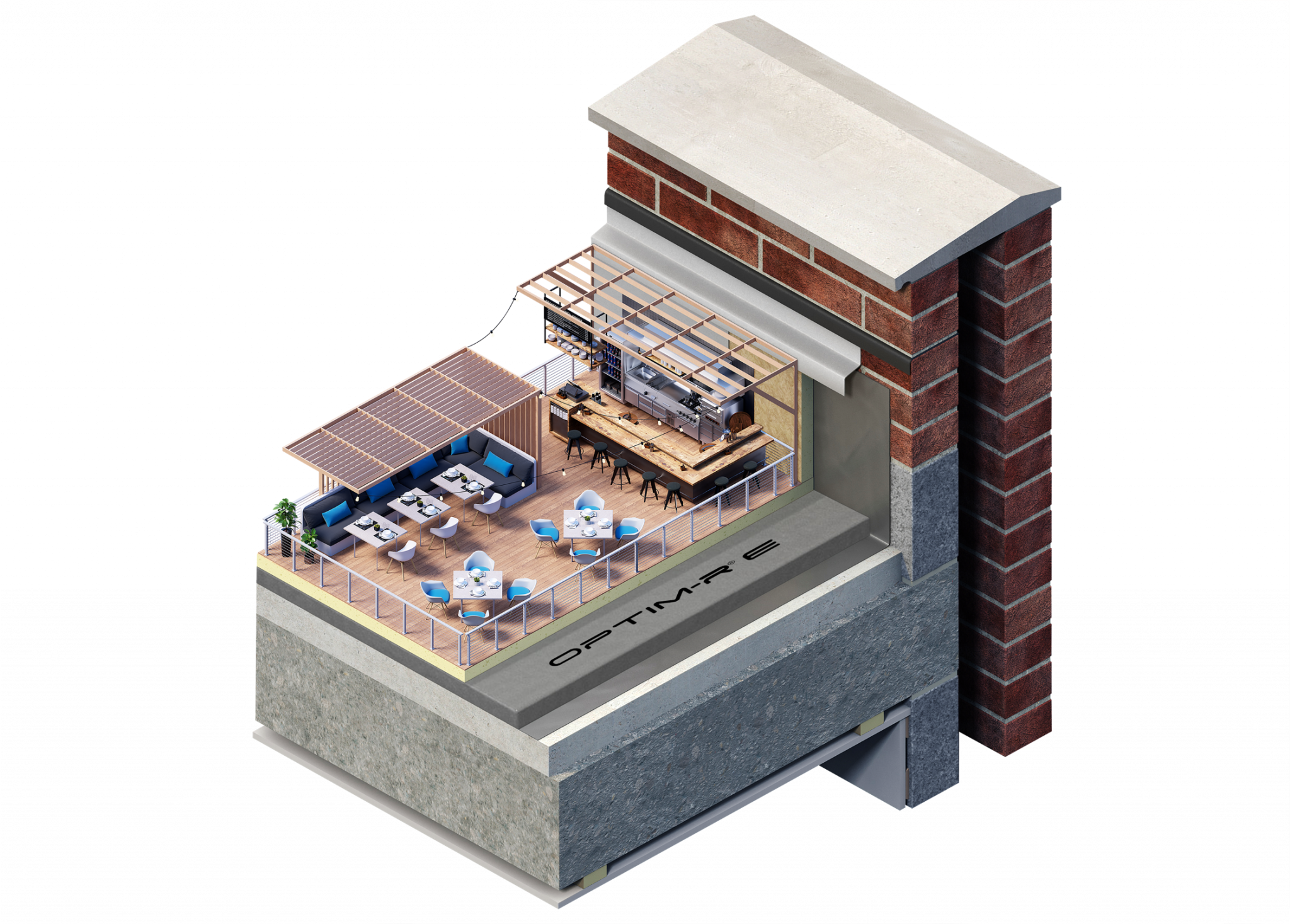

Although the push for code adoption that requires higher thermal performance has been stalled nationally, these requirements are already in place in some large municipalities. The use of traditional materials, such as polyiso and mineral wool products, could lead to a cost increase due to the large thickness required to meet code and space constraints, especially in retrofitting projects.

On the residential side, wood-frame houses now must go to a 2×6 construction to accommodate thicker insulation. New technologies that offer higher insulation value could be a viable option.

What are the life-cycle carbon implications of next-gen insulation products, and how do they factor into whole-building embodied carbon assessments?

It depends. Current standards do not allow environmental product declarations (EPDs) to incorporate the Impact of State D, “Reuse-recovery-recycling potential,” in the life-cycle assessment (LCA).

In addition, the Mass Balance Approach is not allowed when calculating GWP. These restrictions limit the adoption of recycled materials and biobased ingredients. On the other hand, manufacturers are beginning to pay more attention to the product’s environmental impact during the design phase of the development, selecting raw materials with lower GWP, and optimizing the manufacturing process to minimize the product’s GWP.