AI-driven forestry meets mass timber: A sustainable building revolution

Jaime Alvarez, vice-president of marketing at Garnica, spoke to Construction Canada about the future of sustainable forestry and the role of artificial intelligence (AI) in revolutionizing sustainable wood harvesting.

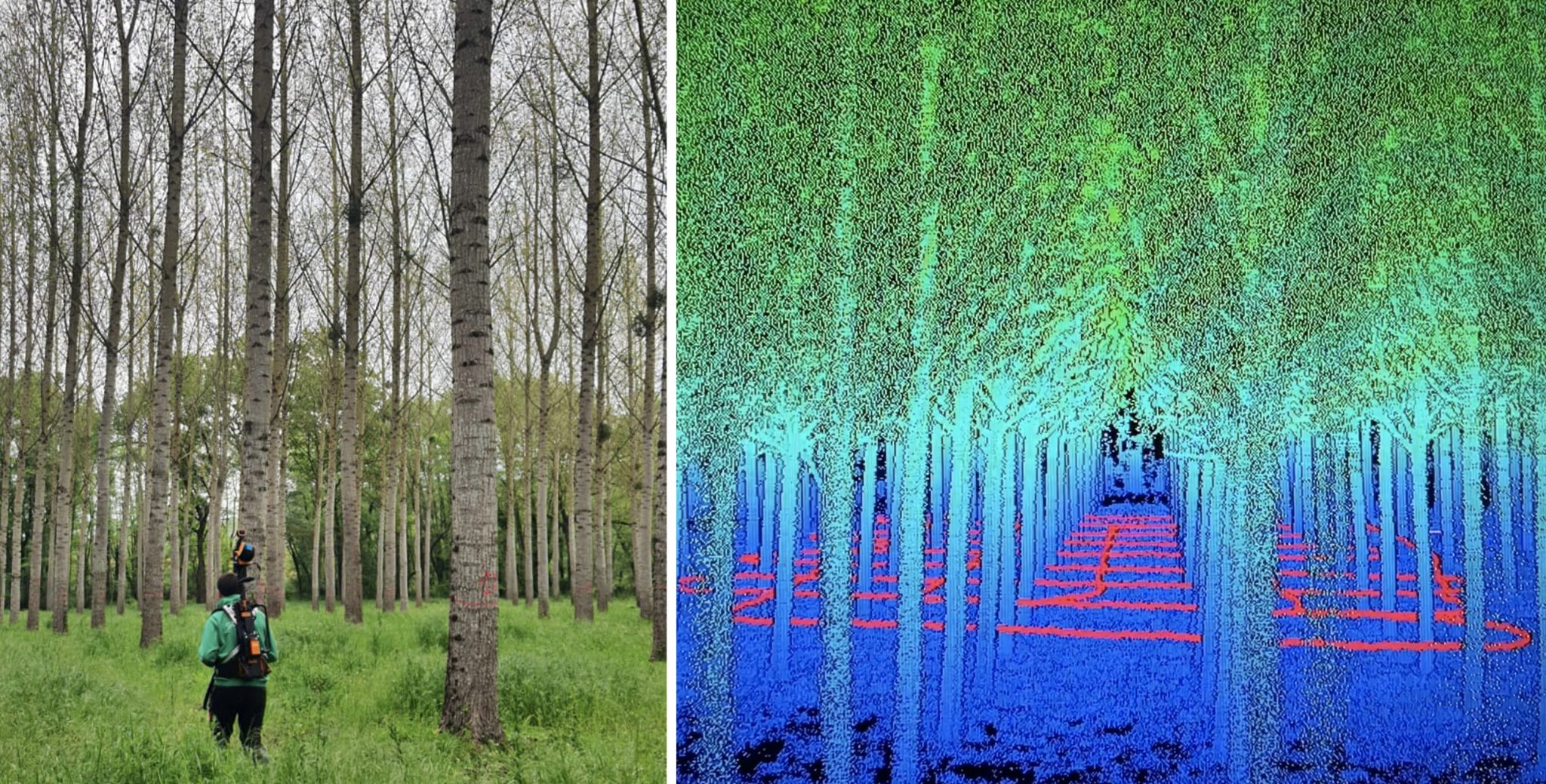

AI is transforming construction by accelerating innovation in sustainable forestry and wood product manufacturing. With current mobile apps, forest technicians, tree farmers, and forest rangers can identify damage to trees and the cause by simply taking a picture of a tree. With technology such as this, one can now make quick and informed decisions regarding timber harvesting.

Beyond the forest, AI is transforming the entire supply chain. It enables demand forecasting, smarter inventory management, and even route optimization to reduce emissions and improve delivery speed. With tools such as geo-tagging and digital tracking, users can ensure every panel is traceable back to its certified source, strengthening transparency and accountability throughout each product’s life-cycle.

AI-powered platforms also support seamless collaboration between forestry and secondary manufacturers by automating alerts and streamlining order management. In a sector where timing, sustainability, and resource efficiency are everything, these technologies are not just helpful—they are essential to building a more sustainable future.

Plywood is more eco-friendly than solid wood, plastic, or metal. It is inherently more resource-efficient than solid wood because it is made by bonding thin layers, or veneers, from fast-growing tree species such as poplar. Poplar trees are among the most efficient at absorbing CO2, making them a powerful ally in the fight against climate change. Compared to plastic and metal, plywood has a lower carbon footprint, both in terms of raw material extraction and energy used during manufacturing.

“Extremely viable and increasingly popular,” says Alvarez when asked how viable plywood is as a long-term, sustainable building material for large-scale construction projects. “Engineered wood products like plywood and cross-laminated timber (CLT) are being used in schools, commercial buildings, and mid-rise housing thanks to their high strength-to-weight ratio, design flexibility, and low environmental impact,” he adds.

Alvarez notes that tiny homes, especially in Western Canada, are gaining popularity. As the demand for compact, efficient, and sustainable living increases, many builders are turning to high-performance, lightweight and fire-resistant plywood panels for cabinetry, wall systems, and even structural components.

Beyond that, mass timber construction continues to gain momentum across Canada. Projects such as Brock Commons Tallwood House in Vancouver, one of the tallest mass timber buildings in the world, showcase how engineered wood and prefabricated products are revolutionizing the construction industry.