Closing the cracks: Why cavity walls matter

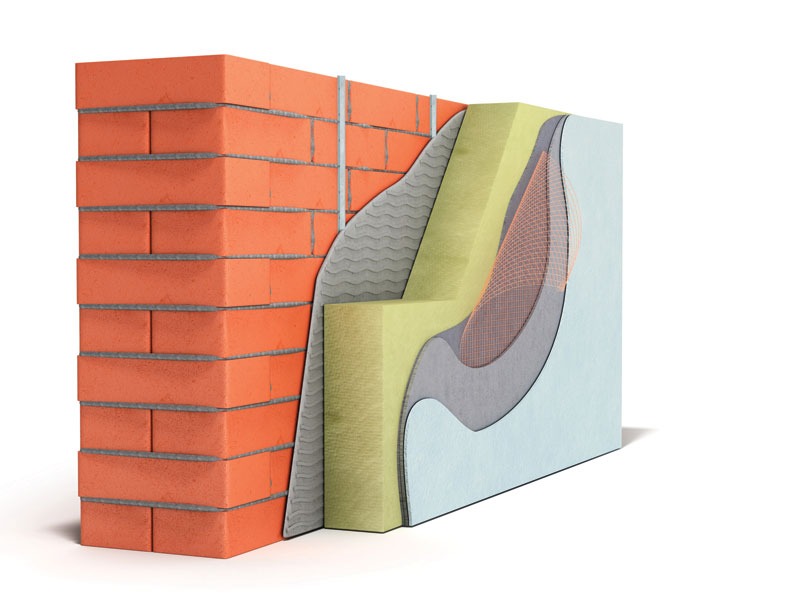

Whether working on a house or alongside a team for a commercial property, insulation is always a priority for energy efficiency and cost savings. Contractors and clients alike often forget to invest in cavity walls—which have an air gap between two layers for heat retention—as they do with solid walls.

Establishing a quality cavity wall requires as much attentiveness, despite its performance advantages. When installed properly, cavity walls provide a golden opportunity to minimize escaping heat and moisture accumulation. These best practices will help ensure a successful installation process.

Use the right materials

Households and professionals are trying to find ways to save their wallets and carbon footprints by leveraging cavity wall insulation. Cavity walls are often exposed to water and varying air temperatures. Therefore, the materials must consider these influences. High R-values and thermal performance are key factors which vary based on location and wall characteristics. For example, cavities with 2×4 and 2×6 studs only have a value of R–5.5 for the space they take up, depending on the wood’s characteristics.1

Mineral wool

Mineral wool is commonly used in industrial facilities with cavity walls due to its insulation properties. The installation process is straightforward, and the product is generally more suited for commercial budgets than residential options despite a higher price point. It has quality thermal performance, fire resistance, and sound absorption, which are crucial for environmentally susceptible parts of the building.

Polyurethane foam

Polyurethane foam is recognized for its high R-value relative to its thickness. It can be applied in thin layers while providing effective air-sealing properties comparable to thicker insulation materials. It also resists water well, meaning the cavity is less likely to develop mould and mildew. Since the foam can be sprayed, filling in crevices and injecting it into the cavity without too much destruction is painless.

Although this material increases fire risk in a building, flame retardants can help reduce these characteristics. Some researchers are testing the ability of options such as metakaolin, a geopolymer, to change the insulation’s pore sizes to make it less susceptible to these dangers.2

Expanded polystyrene (EPS)

EPS is one of the most lightweight insulation materials on the market.3 Often, it comes in blocks, making it effortless to slide into cavities with a wide enough opening. It is also one of the most affordable. It still has a notable R-value for creating optimal efficiency.

Extruded polystyrene (XPS)

XPS has many of the benefits of EPS for cavity walls, including moisture control and thermal performance. It may be favoured over EPS because it has fewer air pockets and naturally minimizes compression. Even if the cavity insulation needed to be tended to, the boards are simple to slot into the wall.

XPS may also be preferred because of its recyclability and ability to reduce energy consumption. These features lower a structure’s overall greenhouse gases. Manufacturers can remelt XPS boards and reclaim thermoplastic resin to fashion it into more insulation or roofing components if necessary.4

Infrastructure for this is minimal throughout North America, with reclamation rates varying by manufacturer. However, some successful projects, including a recycling effort at an international airport, were able to salvage 90 per cent of XPS for repurposing.5

The material could be a popular choice among customers, especially as recent surveys show that 37 per cent of buyers are willing to pay a

five per cent premium for eco-friendly alternatives.6 These insights should be shared with clients, as cavity wall insulation interest may align with energy-efficient or sustainable building goals.

Install insulation correctly

The quality and choice of materials matter only if they are installed appropriately. The process slightly differs from that of solid walls. First, ensure there is enough space to insert insulation. When inserting boards or spraying, confirm every gap is covered and uniformity is present. Haphazardly filling the space or neglecting a review may leave open cold spaces, compromising the rest of the insulation’s integrity.

Also, review national guidelines for greener, more effective installation. The PERSIST initiative is one example, and many of its priorities apply to all insulation types. The strategy highlights the importance of a rainscreen in making buildings airtight and dry.6

Leverage technology

Sensors and artificial intelligence (AI) are changing every industry, including insulation. AI in structural design could discover performance variances from every step, mitigating material weathering and waste by identifying optimal design. Studies prove AI is helpful for enhancing a building’s energy efficiency by considering the structure’s comprehensive elements, including how windows could lower an envelope’s effectiveness.8 Most studies reviewing AI’s ability to aid insulators analyze diverse parameters, demonstrating its versatility, such as thermal conductivity, heat transfer coefficients, reflectance and heat inertia.

For example, AI sensors may find damp spots that need to be addressed before anything is put inside. Using computer vision and advanced cameras, installers could easily detect weep holes that require filling without laborious and time-consuming manual inspections. Machine learning algorithms are increasing in speed and accuracy, notably in dark environments where quality control is harder to discern. Studies show that semantic segmentation algorithms had an accuracy of 63.1 per cent in these challenging conditions.9

Performance analysis for buildings, particularly large structures, is commonly conducted for both new and retrofitted projects. AI can use the building’s data and specifications, including orientation and historical weather data, to assess the specific needs of each cavity wall. A wall exposed to more sun or water could have a more considerate composition than the opposing part of the facade.

After the insulation is in the space, contractors may use AI for ongoing maintenance and structural health monitoring. It can review how well the structure copes with concerns such as thermal bridging, visualizing analytics shifts over time. Connectivity with smart software solutions makes cavity walls straightforward to observe without peeling away their layers. These technologies have been available for years, but seek to enhance capabilities with complements like AI.

Choose water and fire resistance

Cavities are prone to other environmental influences compared to solid walls. Therefore, the insulation must contain qualities that outsmart its environment. For example, a crack in a brick is enough for problematic water ingress. Long-term performance can be protected by choosing water-resistant insulation types, such as XPS, mineral wool, and sprayfoams. Incorporating a drainage solution as a fail-safe should also be considered, and it is often a code requirement, depending on the location. The right insulation is critical, primarily if the area is known for heavy rains or is near a water body.

The same is true for fire resistance. The insulation type should slow fire spread (e.g. mineral wool). This is why many masonry chimneys and cavity walls use mineral wool—it does not promote combustion.10

Another bonus best practice is reinforcing the external cavity walls, whether the job is a retrofit or a new build. The outside layers are another obstacle to keeping flames from worsening. Focusing as much on the facade’s strength as the insulation during the design process of the base structure can increase the value of cavity wall insulation and its climate-resistant qualities.

Contractors may also use AI to assist in structural design to find temperature variances and pools of moisture. Even if installers make mistakes, the equipment could discover early mould growth or overly dry regions to warn operators of potential fires before

they exacerbate.

Ventilate thoroughly

To ensure optimal cavity wall performance, it is important to install more than insulation. Moisture and thermal movement are inevitable, no matter what material is present. Supplementary ventilation will stop deterioration and encourage a longer service life.

Fixtures such as ventilation holes remove water buildup that may have entered from the outer leaf. While drains and openings are ideal for this, consider assets such as air bricks. They connect the insulation to make it sturdier while managing the enclosed environment. Air bricks support wooden joists while preventing moisture accumulation that would cause unwanted odours, rot, or disruptions to internal condition regulation.

Cavity wall insulation, thermal resistance, and AI in structural design

Cavity wall insulation is a solution that owners, designers, architects, engineers, etc., should deploy more frequently. Substantial environmental and financial savings can be discovered, along with boosted indoor comfort.

Many have avoided insulating cavity walls in the past because of literal barriers getting in the way, such as high costs to remove potential debris, or mould while addressing supplementary ventilation. With these best practices and novel technologies, it is possible to effectively fill any cavity to preserve a building’s efficiency and resource management.

Notes

1 See.

2 Read.

3 Refer.

4 Review.

5 Read.

6 Refer.

7 Learn more.

8 See.

9 Learn more.

10 Refer.

Author

Emily Newton has more than 10 years of experience creating compelling content for the construction, manufacturing, and supply chain industries. Her work has been published in a range of industry magazines and online platforms. As the editor-in-chief at Revolutionized, she enjoys researching the latest scientific breakthroughs.