Mitigating water risks: Advanced containment solutions

Safeguarding against floods, spills, and sprinkler discharge is critical across industries and facilities. Containment barriers are ideal for protecting facilities and their contents from these potential hazards, and many options are available. Barriers cater to a wide range of applications with both automatic and manual versions, ensuring businesses are equipped to handle various emergency scenarios without compromising operational efficiency. This article discusses the technology behind these barriers, their practical applications, and their benefits for different industries.

Industrial and commercial environments must always be on guard against floods, hazardous spills, and sprinkler discharge. Hazardous material spills with uncontained runoff can result in environmental contamination and expensive fines. Automatic sprinkler systems are lifesavers, but failure to contain their discharge water can be harmful to the environment and disastrously expensive to mitigate. Floodwater damage can be costly, even at lower levels of a foot or less. Existing drainage systems and minimal containment measures are insufficient, especially for facilities working with hazardous materials. The need for robust solutions is urgent, especially as environmental regulations grow stricter and industrial operations become more complex.

Flood risks continue to rise

Uncontrolled water entry is a threat to industries operating in low-lying areas. Industries that house sensitive materials are especially concerned about floods. More than 80 per cent of flood damage is caused by less than 381 mm (15 in.) of water, but just a few inches of water in a warehouse can cause stock loss and disrupted operations. Flooding is becoming harder to predict due to climate change. According to the World Resources Institute, the number of people affected by flooding will more than double by 2030. Floodplains are expected to shift and expand due to more frequent and intense storms. This growing instability increases the threat to businesses worldwide and makes reliable flood containment measures even more important. Unaddressed, these risks lead to escalating costs and greater liability.

The threat of flooding does not stop at external factors, either. Internal sprinkler systems designed to protect against fire can cause water containment issues, as sprinkler water can mix with hazardous chemicals and contaminate areas it flows into. Even non-hazardous chemicals can be problematic from an environmental standpoint. Spill migration has the potential to be catastrophic. Even a small spill can cause contamination, forcing work delays and costing millions in cleanup and downtime. Without adequate containment systems to prevent contaminated water from leaving the room or facility, these events can result in regulatory violations and environmental damage. Facility managers know that these risks are not just limited to large-scale disasters. Even a minor incident can accumulate and cause expensive consequences. This underscores the need for proactive flood and spill containment strategies.

Floods, spills, and leaks can be costly and harmful

There are many financial, operational, and safety risks associated with uncontained water or chemical spills. Fines for environmental violations from regulatory bodies, such as the Canadian Environmental Protection Act (CEPA), can reach hundreds of thousands of dollars, not to mention the added cost of cleanup. A single uncontrolled spill in a chemical storage facility can mean fines for allowing contaminated runoff to enter local water supplies or sewage systems. Companies can also face insurance premium increases and a loss of business due to non-compliance with environmental safety standards. In addition, the bad press from an incident has long-lasting consequences. A damaged reputation undermines the trust of consumers and impacts business value.

Downtime caused by floodwaters or chemical spills can be devastating. Facilities that depend on continuous operation, such as food processing plants, pharmaceutical manufacturers, or logistics hubs, suffer from interrupted production lines and delayed shipments. Employee safety is also a concern. Hazardous material spills can pose severe risks to worker health, and flooding can lead to structural damage, mould, and long-term safety hazards. Exposure to dangerous chemicals may require emergency response efforts and even facility evacuations. Uncontained floods, spills, and leaks can escalate costs and lead to greater liability. Solutions are needed, especially as environmental regulations grow stricter and industrial operations become more complex.

Automatic pop-up barriers control floods and spills

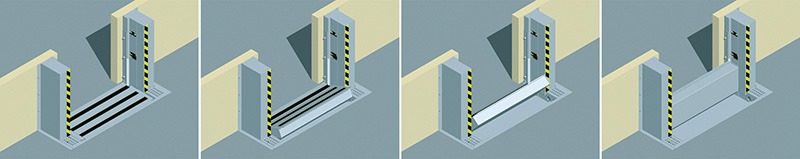

Advanced automatic pop-up barriers activate without needing electricity, compressed air, or human intervention. This innovative technology is beneficial in situations where a rapid response is critical. When a liquid flow reaches the barrier, it is collected in the sump that houses the barrier wall. As the volume of fluid increases, it displaces the wall from its horizontal position. The built-in mechanism then brings the barrier to its full locked and upright position, containing or holding back the impending liquid with a watertight seal. This fast response to a spill or flooding event can save time and money on cleanup operations. After the event, pop-up barriers can be easily reset and reused. The automatic pop-up feature ensures the facility remains protected even without personnel, preventing damage and lowering the risk of hefty fines.

Constructed from solid, welded Type 304 stainless steel with a Teflon gasket and built to withstand harsh conditions, pop-up barriers are suitable for many settings. Offering chemical resistance and long service life, they are made in a one-piece factory-adjusted design, lubricated, and easily installed in existing doorways. Designed to lie flat on the floor when not in use, there is no need for berms or ramps, and retention heights of 305 mm (12 in.), 457 mm (18 in.), and 610 mm (24 in.), respectively, are available. Available sealed widths range from 1,016 to 4,978 mm (40 to 196 in.). Their robust construction supports vehicular traffic up to 5,897 kg (13,000 lb) of axle weight when flat and not in use, making them no problem for busy facilities. Owners should follow manufacturer guidelines for periodic maintenance for peak performance.

Structurally, flood barriers and spill barriers are the same; the difference is how and where they are installed. As flood barriers, pop-up barriers are helpful in protecting infrastructure because they can safeguard low-lying areas, doorways, and other building access points from the influx of floodwaters. By rising automatically when water reaches the barrier’s sump, they provide quick and reliable protection to minimize costly damage to equipment, stock, and even the structural integrity of a building. They are an excellent solution for facilities found near bodies of water and locations vulnerable to stormwater runoff from surrounding areas.

As spill barriers, pop-up barriers serve a valuable function for facilities concerned about sprinkler discharge water. Sprinkler systems are a common fire safety measure in industrial settings, and when the systems activate, water can mix with hazardous materials and lead to contamination. Pop-up spill barriers are NFPA compliant, prevent contaminated water from escaping the facility, and can help ensure that potentially harmful substances do not reach the sewer systems, soil, or waterways. Because they require no power, they are effective even when electric systems are compromised. Commonly found in chemical storage areas, manufacturing plants, logistics hubs, data centres, and food processing facilities, they are also effective across many industries, including pharmaceuticals, automotive, aerospace, and even large retail chains such as Amazon and Home Depot.

Manual barriers provide cost-effective protection

Manual containment barriers are a newer development that offer a practical and cost-effective way to retain polluting fluids. Their chemical-resistant gaskets maintain a tight seal in both hot and cold conditions, and the rigid steel and aluminum design withstands extreme temperatures during fire. A unique clamping mechanism secures the barrier in place between pre-set piers installed at the opening, which eliminates the need for ramps or berms. They work well for protection in areas with less frequent traffic and few pedestrian or vehicle doors to protect, such as warehouse storage zones or secondary access points. Indoors, without traffic, the barriers can remain horizontal and avoid possible leaks. Various styles and sizes of manual spill control barriers are available, including manual insertable, pivoting, loading dock barriers, and step-ramp style barriers. The barriers can be deployed and then removed, making them suitable for temporary use during maintenance operations or in areas that do not face constant risk, and are less intrusive because they do not require the extensive site preparation needed for automatic systems. Due to their manual nature, they require personnel to be on-site to activate them, which may not always be possible in emergency scenarios. They are a practical decision for facilities that need occasional spill or flood protection without the need for continuous readiness.

Containment barriers are widely used across many industries, and their effectiveness in preventing water damage and environmental contamination makes them a preferred choice. The wide range of selections allows companies to maintain facility safety and integrity with reliable and automatic protection against floods, spills, and sprinkler discharge. Technology advancements in automatic barriers and the ongoing development of manual alternatives mean more choices are available. The future of this industry will bring new maintenance programs and product enhancements as the barriers continue to safeguard industrial and commercial environments against unexpected water-related incidents.

Author

Steve Eyer is manager, engineered solutions for DENIOS, which provides safety and environmental protection products for North American installations. For more information visit www.DENIOS.ca.