Ensuring concrete quality in North America’s infrastructure

Infrastructure and civil engineering projects play a crucial role in the growth and stability of North America, with the region’s current construction market size estimated at $2.46 trillion U.S. dollars.1 Infrastructure is the backbone of economic development, facilitating trade, transportation, communication, and energy distribution. This importance is further underscored by the $1.2 trillion for transportation and infrastructure spending, including $550 billion dedicated to “new” investments and programs aimed at revitalizing and expanding key infrastructure initiatives, according to recent findings by the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA).2 Quality infrastructure drives economic stability and urban development, attracts investments, supports business growth, and improves the quality of life for residents.

One critical component of modern infrastructure is concrete, a material whose strength and durability are central to the safety and longevity of many structures. However, the integrity of the concrete is not guaranteed by default. Monitoring concrete is essential in ensuring structures meet the highest durability and safety standards. This is also crucial to ensure the quality of concrete, including its strength and integrity, is as specified in the engineering documents and to avoid structural defects, such as delayed ettringite formation (DEF) and honeycombing, during the curation process. Digital solutions are essential for monitoring concrete quality because this technology provides greater project visibility, leading to smarter decision-making and more resilient infrastructure systems. By leveraging digital tools, such as innovative concrete monitoring technologies and platforms, project managers can achieve real-time insights, enabling swift decisions that safeguard the integrity of the built environment for years to come.

The central role of concrete in infrastructure

Concrete is the most widely used building material in infrastructure projects,3 and it plays a crucial role in shaping North America—from the Interstate Highway System to the Hoover Dam. However, the material also presents significant and common challenges, such as cracking, erosion, and curing problems.

Central to the success of these projects is the emphasis on quality, particularly in the construction of concrete structures. Reliable and accurate monitoring of concrete is essential in ensuring these structures meet the highest durability and safety standards. In this context, the digitalization of monitoring processes plays a transformative role, offering enhanced precision and efficiency, and digital tools provide real-time insights throughout the construction process.

Sustainability’s role in concrete infrastructure projects

Sustainability is an increasingly critical factor in modern infrastructure projects. Concrete production is associated with high carbon emissions due to the energy-intensive process of manufacturing cement, a key ingredient in concrete. On the other hand, concrete’s durability makes it a desirable and sustainable material for long-term projects. Internet of Things (IoT) solutions are vital in promoting sustainable infrastructure by ensuring concrete is used efficiently and its lifespan is maximized.

Inadequate monitoring and quality control in concrete structures have economic and human costs. Advanced monitoring technologies contribute to the quality and longevity of concrete structures and support safety and sustainable practices. By optimizing the use of materials and minimizing waste, these technologies help reduce the environmental footprint of construction projects.

Digital IoT solutions in concrete quality monitoring

Traditionally, thermocouples and data loggers were the primary tools for concrete monitoring, focusing on quality control (QC) during the curing process. However, technological advancements, particularly IoT systems, have revolutionized concrete monitoring. Modern IoT-based solutions enable remote and continuous monitoring of concrete through cloud-based platforms, providing real-time analytics and insights. This advanced approach ensures precise tracking of curing conditions, allowing for proactive adjustments to prevent structural defects and optimize concrete quality long after the curing process is complete.

IoT sensors for industrial applications provide visibility into the structure’s lifecycle, from concrete temperature and maturity to concrete strength and long-term structural integrity. These advanced solutions offer remote and reliable access to real-time data and are vital in preventing potential issues. Using IoT sensors, contractors and asset owners can monitor their concrete structures, both during and after curing, in real time, over the entire asset lifecycle. Moreover, IoT solutions enable greater transparency and accountability in construction. With real-time data, project managers, engineers, and stakeholders can make informed decisions, ensuring concrete meets the necessary quality standards.

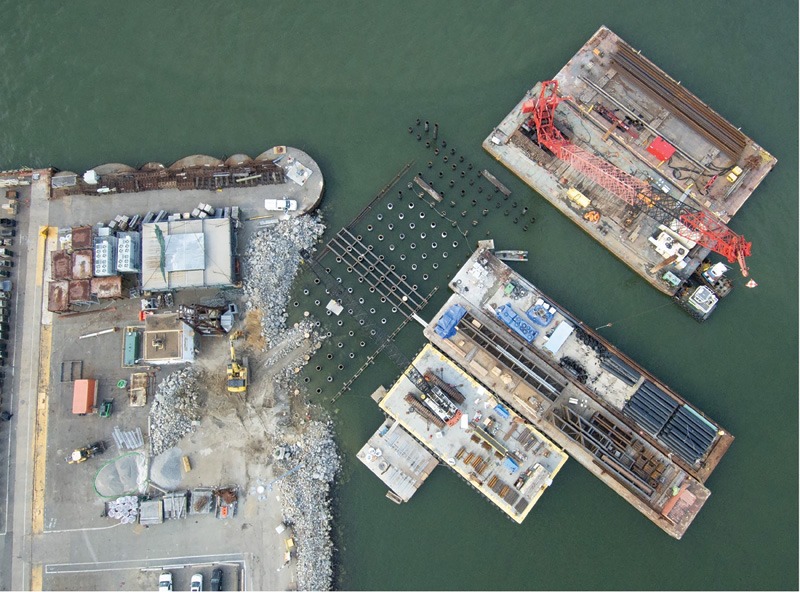

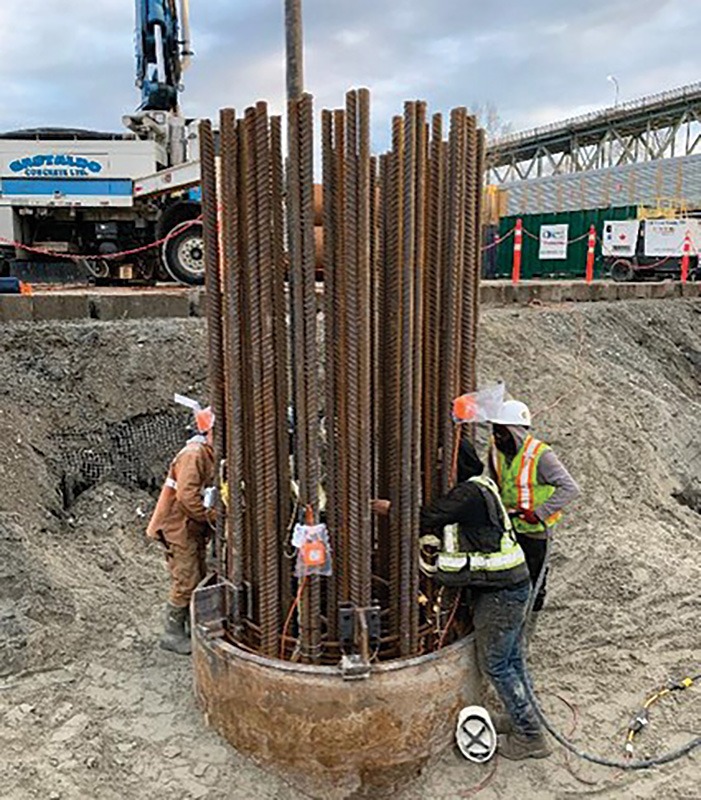

The sensors are ruggedized and robust, providing valuable data that can benefit structures far into the future. IoT sensors are easily installed and can be surface mounted on structures, depending on the type of infrastructure, and have capabilities to withstand and monitor severe temperatures, pressure, strain, vibrations, and extreme weather conditions. Concrete monitoring systems are typically installed during or just before the concrete pour. IoT sensors can be embedded directly into the concrete or attached to structural elements (e.g. rebar). This timing ensures the sensors begin capturing data from the earliest stages of curing, providing a comprehensive view of the material’s performance throughout the curing process and its operational lifecycle. Monitoring can be both temporary and permanent, depending on the project requirements. In most cases, sensors are temporary and sacrificial for curing and early-stage quality assurance.

Concrete monitoring systems are typically specified in engineering design documents or thermal control plans (TCPs) based on project needs, environmental conditions, and structural performance goals. Specifications include sensor type, placement, monitoring duration, and tracking data parameters (e.g. temperature, temperature differentials, and maturity). Engineers ensure the selected system aligns with the project’s durability and safety requirements while meeting regulatory and sustainability standards.

The consequences of poor concrete quality in infrastructure

With an uptick in extreme weather, there is an increasing demand for resilient infrastructure that can withstand natural disasters and climate change. Poor concrete quality leads to higher maintenance costs, shortened lifespans, and potential safety hazards.

Several high-profile infrastructure failures have been linked to poor concrete quality. For example, the Surfside condo collapse that killed 98 people in Surfside, Florida, in 2021.4 As one of the largest building failures in U.S. history, this incident highlights the importance of constructing and maintaining buildings to withstand a host of weather conditions. While the investigation is ongoing, installing IoT sensors can help prevent these types of incidents and allow contractors to understand the conditions of their structures from the start, ensuring safe and reliable foundations are laid.

Conclusion

As cities expand and demands on infrastructure increase, the quality and durability of construction materials, particularly concrete, become more critical than ever as infrastructure serves as a key pillar in the foundation of North America’s growth and stability. Prevention and early detection will lead to cost savings since proper preventive maintenance can be performed before problems worsen.

IoT solutions allow for early repair management, as contractors and asset owners use data to glean precise information from the structure. Digital IoT solutions represent a transformative force in the construction industry by enabling real-time monitoring, predictive analytics, and proactive maintenance. IoT technology acts as a powerful tool to prevent issues related to concrete quality and ensure the integrity of infrastructure projects, enhancing safety, reducing long-term costs, and supporting sustainable development by optimizing resources and minimizing environmental impact.

Notes

1 Refer.

3 Learn more at www.rsc.org/images/Construction_tcm18-114530.pdf

Author

Amir Azhari is the co-founder and chief commercial officer of Brickeye. He received his BSc and MSc in materials engineering, holds an MBA, and completed his PhD in mechanical engineering at the University of Waterloo. Azhari has a broad range of expertise in industrial IoT, fibre optic sensing technologies, additive manufacturing, advanced materials, and nanotechnology. He has a strong passion for developing advanced technologies and solutions that assist with enhancing productivity and reducing risk in the construction industry. Azhari has co-authored more than 20 papers in peer-reviewed scientific journals and international conferences, book chapters, and patents.