Designing EPCOR Tower

Images courtesy AECOM

The gearless machines were specified because they are more energy-efficient than other types of elevators. The installation includes remote elevator monitoring and an elevator management system that allows the building operator in-house computer access to all elevator operating parameters. This facilitates enhanced security and permits daily performance adjustments.

Mechanical

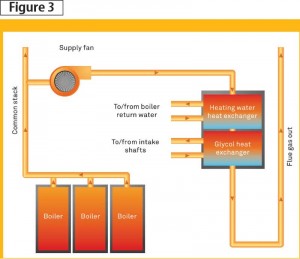

The building’s heating system comprises conventional boilers breeched together to combine the flue gases before entering a stack condenser (Figure 3). Two separate heat exchanger coils in the stack condenser (one with water, one with glycol) extract heat from these flue gases. Condensation forms when the gas temperature is lowered below its dewpoint and both latent and sensible heat is extracted. Water from the first heat exchanger is returned to the heating water system and preheats the boiler return water. Glycol from the second heat exchanger is used to pre-heat outdoor air intake shafts.

An exhaust heat recovery system is provided to capture waste heat from the building’s general exhaust. A heat recovery unit, located at the exhaust outlet, captures the heat in the exhaust air and returns it to a heating coil in the main tower air handling unit via a glycol run-around loop. The exhaust air heat recovery is capable of providing a 19-C (66-F) temperature rise for 37,754 L/s (80,038 cfm) of outdoor air.

Free cooling can be achieved when the outdoor air wet bulb temperature is less than the chilled water temperature—in this case, 6.7 C (44.1 F). In the cooler months, the chillers are bypassed and only the cooling towers operate. This is accomplished by providing the building’s cooling towers with integral immersion heaters capable of running year round.

A unique system of earth tubes is used to pre-heat and pre-cool the building’s outdoor air. Earth tubes rely on the principle of geothermal exchange between the air and the surrounding earth (Figure 4, page 14). The ground can be used to heat air in the winter season and cool air in the summer season because the ground temperature essentially remains constant below the frost line.

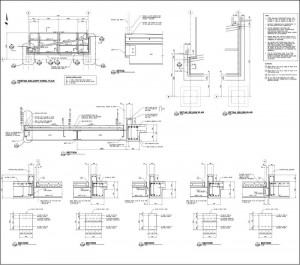

With a thermally conductive material as a separation, the heat transfer is greatest when the surface area in contact with the ground is the greatest. Using a low air velocity (about 1.02 m/s [200 fpm]) through the earth tubes allows maximum heat transfer to occur by providing adequate lag time. The EPCOR Tower has two vertical intake shafts that run down the exterior of the parkade walls and are pre-heated with low-grade heat recovered from the stack condensing boiler plant. The two shafts then turn 90 degrees to run horizontally below the parkade structure.

The earth tubes loop around the building’s core before connecting to the main tower air handling unit that provides the rest of the conditioning. The desired temperature rise inside the earth tubes is from –34 to 6 C (–29 to 43 F), the latter being the constant ground temperature below the frost line, resulting in a 40 C (72 F) delta.

Each earth tube needed to be 80 m (262 ft) in length, assuming a heat transfer rate of 0.5 C/m (10 F/ft). The actual length of the constructed earth tubes are 116 and 97 m (380 and 318 ft). They are 9.5 m (31.2 ft) wide and 2.5 m (8.2 ft) high and have an airflow rate of 18,877 L/s (40,019 cfm) each. The earth tubes are designed for the maximum load—in Edmonton, this occurs in heating mode.

A rainwater collection tank, which is built into the tower structure below the parkade, provides water for flushing of water closets and urinals. The tank volume is 725 m3 (191,525 gal) and can provide 4434 m3 (1,171,443 gal) of annual domestic water savings. This, in combination with dual-flush water closets and low-flow urinals, faucets, and showers, results in a 63 per cent water use reduction.

Electrical

The main site electrical room, site communications room, vista cubicle room, and EPCOR’s data centre are all strategically located on the P1 level of the underground parkade. There are dual high-voltage incoming feeds from two EPCOR substations providing redundancy. The tower’s core includes one electrical room per floor and two communications rooms at each end of the core. The dual telecommunications risers on each floor provide flexibility and redundancy for the tenants.

An average of 3 W/sf of receptacle load is supplied for the tenants, which does not include HVAC or lighting. Individual metering is available and a high-performance generator is located on the third floor in the southwest mini-tower for essential and building emergency/life safety loads.

Lighting includes high-performance and energy-efficient T5HO lamps as a building standard. Lighting levels have been designed in accordance with Illuminating Engineering Society of North America (IESNA) recommendations for all areas.

Parkade, service, and storage rooms

- Target lighting level: 100 lux in parking areas, 200 to 300 lux in all vehicle and pedestrian circulation areas.

- Luminaire selection: surface strip fluorescent.

Typical floor (open office) and enclosed private offices

- Target lighting level: average of 500 to 700 lux maintained to meet lease requirements.

- 2. Luminaire selection: recessed direct/indirect in 2.4-m (8-ft) lengths with double lamp T5HO cross-section provided for tenant installation (complete with integral occupancy and daylighting sensors).

Meeting/breakout rooms

- Target lighting level: 500 to 700 lux average maintained to meet lease requirements complete with integral occupancy and daylighting sensors.

- Luminaire selection: recessed direct/indirect in 2.4-m lengths with double lamp T5HO cross-section provide for tenant installation.

Public lobby areas and main/second floors

- Target lighting level: 300 lux ambient.

- Luminaire selection: for ambient lighting, recessed direct 229 x 229-mm (9 x 9-in.) square potlights with compact fluorescent and metal halide lamps with high-performance optics (lamps were chosen based on the area ceiling heights); for accent lighting, solid-state light-emitting diode (LED) fixtures with colour-changing and dimming capabilities to highlight the architectural features inside the public lobby areas.

Exterior luminaries

The selected exterior luminaires provide ambient lighting by using high-performance pole-mounted metal halide lamps throughout the plaza areas on the main floor. Solid-state LED fixtures with colour-changing and dimming capabilities were specified to highlight the architectural features at the exterior façade lighting at the top of the tower.

Local controls are provided for all lighting installations within the facility. Use of occupancy sensors, daylighting sensors, and dimming systems are incorporated into the luminaire designs where possible to maximize user comfort. All luminaires are equipped with addressable ballasts that can be controlled via a centralized computer control system and then interfaced with local sensors in addition to local user workstation controls.

The lamp sources meet specific design criteria for all areas. Linear fluorescent T8 lamps were specified for the parkade, service rooms, and washrooms throughout the tower based on lighting performance and lamp life considerations. T5HO lamps were specified for the tenant areas based on lighting performance and lamp life considerations. Metal halide, LED, and fluorescent sources are used for all internal building applications where appropriate; metal halide and LED sources are employed exclusively for all exterior building applications. The use of incandescent lamp sources has been avoided.

Emergency and night lights are provided by using base building luminaires serviced from the emergency generator. Emergency and night lighting luminaires are located along all designated emergency egress paths.

Life safety

The security system includes a closed circuit television (CCTV) monitoring system. The system is composed of cameras, monitors, and video recording equipment. The access control system comprises card readers.

The life safety system is a fully addressable, dual stage fire alarm system. Sprinkler fire protection is required and used throughout the building. It is fully monitored by the fire alarm system and incorporates a floor-by-floor smoke evacuation system.

Conclusion

EPCOR Tower acts as a catalyst for the rejuvenation of the northern edge of downtown Edmonton. Qualico’s courageous and visionary direction to develop Station Lands on an abandoned rail yard will help position Edmonton as a leader in urban revitalization in North America.

The authors would like to thank Jillian Pederson (AECOM Mechanical), Andy Smith (AECOM Structural), David Brown (EIDOS Consultants), and Mike Roper (Ledcor) for their invaluable assistance in the preparation of this study.

Honor Morris, BA, is media relations manager for Kasian Architecture Interior Design and Planning Ltd. She has 20 years of journalistic experience. Morris can be reached at honor.morris@kasian.com.

Christiaan Odinga, BFA, BArch, MRAIC, is an associate with Kasian, based in its Edmonton office. He has more than 20 years of professional experience and is the lead designer and project manager for EPCOR Tower. Odinga can be contacted via e-mail at christiaan.odinga@kasian.com.

Ken Cantor is the manager of Qualico’s commercial division in Edmonton. He has been responsible for the development, acquisition, and management of commercial properties valued in excess of $500 million, including neighbourhood shopping centres, retail power centres, major downtown mixed-use development projects, and downtown and suburban office space. Cantor can be reached at kcantor@qualico.com.