Standards for residential hardware raise the bar

by Katie Daniel | November 14, 2017 4:11 pm

[1]

[1]By Michael Tierney

Since the program first launched in 1964, the American National Standards Institute/Builders Hardware Manufacturers Association (ANSI/BHMA) standards have traditionally focused on hardware for commercial buildings. Architects and specifiers charged with choosing hardware for single-family homes and high-rise multifamily dwellings were required to install products conforming to commercial hardware standards—sometimes over-designed for residential applications—or use products that were not tested to any standards.

Recognizing the gap between requirements for commercial and residential hardware, BHMA published its first standards for residential products in 2015. Earlier this year, the association took this up a notch by starting a campaign to educate homeowners about builders hardware, using its BHMA Certified Secure Home label. (See also the association’s educational web portal, www.securehome.org[2].)

Need for residential standards

The potential value of standards tailored to residential applications, including single-family homes and multifamily dwellings, is huge. Presently, there are only two residential standards for builders hardware—ANSI/BHMA A156.39, Residential Locksets and Latches, and A156.40, Residential Deadbolts. These documents set the highest performance standards when it comes to the security, durability, and finish of a home’s door hardware.

In the residential hardware marketplace, the governing principle is caveat emptor (let the buyer beware). Inferior products are common in the market, but without reference to specific standards, how could one identify these products as subpar? It is difficult or impossible to objectively differentiate between the levels of quality for specific hardware without standards.

Residential standards also increase the possibility of more hardware choices. This means specifiers can select the best value with the assurance the quality level is appropriate for the application.

New standards build on basics

The first thing a specifier should understand about residential standards is they build upon commercial ones. This means professional specifier should be familiar with both. One of the oldest BHMA standards is ANSI/BHMA A156.2, Bored and Preassembled Locks and Latches. Hardware specifiers for multifamily dwellings may already be familiar with A156.2, as well as related standards for commercial products, including ANSI/BHMA A156.12, Interconnected Locks and Latches, and ANSI/BHMA A156.13, Mortise Locks.

The availability of industry standards specifically for residential dwellings does not negate the need for knowledge about these commercial regulations. In fact, test methods used in residential standards are quite similar to the ones for commercial hardware. Residential standards simply provide hardware specifiers with more options, and bring greater clarity to the marketplace.

Working with homeowners

The next thing a specifier should know about residential standards is the grading system supported by these codes can be easily communicated to owners in simple terms.

With the Certified Secure Home label, consumers can now easily identify which locksets and deadbolts have been tested and certified by BHMA. The products are rated on a scale of C (good), B (better), and A (best)—letters instead of numbers to avoid confusing them with commercial grades. Further, each certified product receives three ratings because there are a trio of different categories—security, durability, and finish. Each area of testing leads to a separate rating in that category.

Specifiers can use their expertise—their ability to understand nuances of underlying tests—to evaluate these features in terms of benefits to a homeowner.

[3]

[3]Comparison with commercial grades

As mentioned, the tests for residential hardware are similar to those for commercial products, with the exception the commercial ones only receive an overall grade after passing all of the tests in each of the categories. Hence, more choices are available to specifiers of locksets and deadbolts when it comes to single- or multifamily housing. For example, if security is a greater priority to a homeowner than durability or finish, then one might consider purchasing a lockset in which security has received a higher (or equal) rating compared to durability or finish.

It should be noted an A rating in residential standards does not correspond exactly to any grades from the commercial standards. One should consult the standards for both the exact test conditions and the performance requirements (e.g. the number of cycles and forces applied during the testing).

It should also be noted a C rating means the product has passed rigorous testing for that category—an ANSI/BHMA rating sets it apart from products that have not been tested and certified. When properly selected for application, the performance of a product with a C rating will not disappoint—it will perform to expectations and hold up to abuse very well.

Interconnected locks

Local building codes may sometimes mandate interconnected locks for safe egress in multifamily dwellings. An interconnected lock is one that operates the bored lock (or latch) and the deadbolt with one motion. It is a safety feature that allows for quick egress in the case of a fire or other emergency. While interconnected locks are not a requirement in single-family homes, they are mandated by law in multifamily homes in some jurisdictions. It is important to always be up to date with local building codes.

In cases where interconnected locks are required, specifiers should be completely familiar with ANSI/BHMA A156.12, which is suitable for light-commercial applications.

Bored versus mortise locks

Mortise locks are most often used in commercial building applications, although bored locks are also widely employed. While bored locks are most frequently specified for residential applications, it is not uncommon for mortise locks to be specified in residential applications, too, especially for main entrances and upscale residences.

This state of affairs is reflected in the standards. No new residential standard has been developed for mortise locks per se; further, the new residential standards do not cover mortise locks, although some mortise-type deadbolts are covered by ANSI/BHMA A156.40. Specifiers must refer to the existing ANSI/BHMA standard for mortise locks—ANSI/BHMA A156.13. Considering that high-end mortise lock applications will demand the highest level of quality, it may well be redundant to create a separate residential standard for mortise locks.

Comprehensive testing

The residential standards were developed in co-operation with builders hardware manufacturers, testing laboratories, and other stakeholders, and after detailed tests for security, durability, and finish.

For example, there is an array of individual durability tests, including versions that test the bolt in various unloaded and preloaded configurations, the chassis, the cylinder and keyway, and various other components of the lockset. These durability tests include force, torque, and cycle tests. To receive a rating in durability, the lockset must meet the requirements set forth in the standard for each durability test.

Similarly, many different security strength and destructive tests are aimed at forcibly defeating the locking mechanism using various torque, axial, and vertical loads. Again, the lockset must meet the requirements for every one of these tests to receive the appropriate rating (A, B, or C) with respect to security strength. The finish tests include neutral salt-spray, humidity, point hardness, perspiration, and ultraviolet (UV) light and condensation tests.

Fortunately for testing laboratories, the same testing fixtures in use for existing standards also can be used for the new residential standards (See “Testing Fixtures for Residential Locksets and Latches,” page 54). The main differences between the standards are the requirements for making the Grade (i.e. Grades 1, 2, or 3 for existing standards versus Grades A, B, or C for the new residential standards). While one might see this as BHMA ‘lowering the standard’ for residential applications, it is more accurate to say the association is accurately matching the quality level with light-duty applications. A commercial Grade 1 or even a Grade 2 level of quality would be overspecified for most residential applications.

The cycle and load requirements for residential grades are a lot less stringent than for commercial applications, yet they are very rigorous when compared to inferior products sold in the marketplace. Therefore, even a Grade C is a mark of quality and far superior to untested products.

A full appreciation of the scope of testing can be obtained through reference to the original standards. They also provide precise definitions of all the nomenclature, as well as drawings and descriptions of various types and functionality of residential locksets and latches (A156.39) and residential deadbolts (A156.40).

Conclusion

What do these ANSI/BHMA residential standards mean for specifiers? Professionals involved in residential buildings now have extra guidance when it comes to deciding what products to select for each individual project or application. More products are available, and it is easier to identify product performance.

Nevertheless, ANSI/BHMA A156.39 and ANSI/BHMA A156.40 do not and are not intended to negate the need for existing commercial standards. As with any application of standards, the specifier should understand the criteria and use judgment and experience in selecting the most appropriate product for the application, especially when it comes to multifamily buildings.

BHMA-certified residential products can be found wherever hardware is sold—listings of certified residential products are available online in the BHMA Certified Products Directory. Currently, standards only exist for residential locksets, latches, and deadbolts. However, other hardware used for residential applications (e.g. hinges, thresholds, screen door holders, and gaskets) will be considered for standard development in the future.

Earlier this year, Builders Hardware Manufacturers Association (BHMA) launched a campaign to raise awareness about its standards for residential locksets and latches and deadbolts.

| TESTING FIXTURES FOR RESIDENTIAL LOCKSETS AND LATCHES | |||||||||

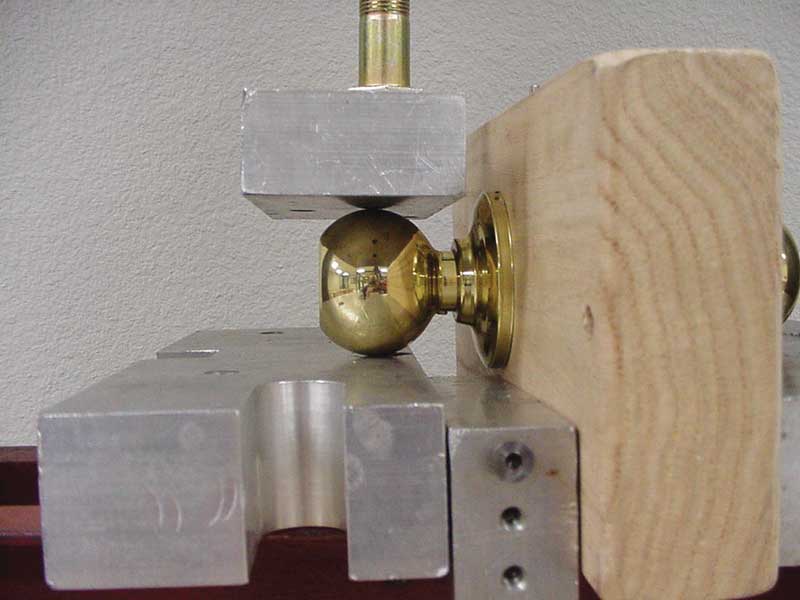

[4] [4]Here are a few examples of testing fixtures from American National Standards Institute/Builders Hardware Manufacturers Association (ANSI/BHMA) A156.39, Residential Locksets and Latches. Mechanically operated test door

Chassis cycle test Use samples which successfully passed Durability Tests, 8.1 through 8.5. Cycle locksets to the values in the following table. This test requirement is to simulate pulling a door open with a lever while being resisted by a door closer. Load shall not be applied during latch retraction. Where agreed upon by the manufacturer and lab, the cycle rate may be increased beyond the specified value pending verification that all cycling aspects are maintained. The cycle and load requirements are less than for commercial grade locksets but they are still quite stringent. Non-keyed knob crush test Cycle and Load Requirements

|

Michael Tierney has served as the product standards co-ordinator for the Builders Hardware Manufacturers Association (BHMA) for 17 years, where he co-ordinates the development and revision of BHMA’s performance standards. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principle member on technical committees for the National Fire Protection Association (NFPA), ASTM, and the American National Standards Institute (ANSI); he also chairs the ANSI TAG 162 for Doors and Hardware. Tierney can be reached via e-mail at mtierney@kellencompany.com[5].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/11/standards.jpg

- www.securehome.org: http://www.securehome.org

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/11/lock-key.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/11/Sidebar-3.jpg

- mtierney@kellencompany.com: mailto:mtierney@kellencompany.com

Source URL: https://www.constructioncanada.net/standards-residential-hardware-raise-bar/