Introducing energy recovery ventilation

by Katie Daniel | September 8, 2016 10:48 am

By Steve Ulm

Current Canadian projects indicate energy recovery ventilators (ERVs) are not a fad, but the wave of the future. One project putting this type of HVAC technology on the ‘sustainability map’ is the Montréal-based Centre hospitalier de l’Université de Montréal (CHUM). CHUM’s 185,810-m2 (2-million-sf) expansion (pictured above) makes it one of the largest hospitals in North America. Its 47 ERVs will provide 100 per cent outdoor air for optimal indoor air quality (IAQ).

While most hospitals bring in 50 per cent or less of outdoor air, CHUM’s total 2.8 million-cfm design of 100 per cent outdoor air will enhance IAQ and minimize the escalating global trend of hospital acquired infections (HAI). The ERVs will also significantly reduce the energy costs of conditioning outdoor air.

ERVs work in a variety of ways, but one of the most popular methods for Canada’s diverse climate includes desiccant-based units. Enthalpy wheels outfitted with desiccant materials absorb moisture out of humid outdoor air. This lessens the humidity load conventional air-conditioning systems handle, which results in significant energy savings.

Besides humidity control, heat recovery is another advantage. ERVs can use exhaust air to preheat or pre-cool outdoor air before it is conditioned to a set point, such as 22 C (72 F). For example, heating —––23-C (–10-F) Canadian outdoor air in January to 22 C is a significant expense. However, using 18-C (65-F) exhaust air to preheat the outdoor air will deliver

significant savings.

Aside from the estimated millions of dollars in energy savings over the operational life of CHUM, the healthcare facility’s ERV system will help achieve a Leadership in Energy and Environmental Design (LEED) Silver certification. The downsizing of mechanical equipment due to the energy recovery strategy and other sustainable efforts is expected to displace 40,000 tons of carbon emissions annually. Further, an estimated 55 million L (14.5 million gal) of cooling-tower water will be saved yearly due to cooling system reductions.

Canada’s upward trend in ERV use is also partially due to local code jurisdictions, which are continually adopting more elements of the American Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE) standards. For example, ERVs offer energy-saving advantages to help buildings comply with ASHRAE 90.1, Energy Standard for Buildings Except Low-rise Residential Buildings. They also offer IAQ advantages for complying with ASHRAE 62.1, Ventilation for Acceptable Indoor Air Quality, and ASHRAE 55, Thermal Environmental Conditions for Human Occupancy.

Using, promoting, and teaching ERV

Perhaps the poster child of Canadian ERV is Sheridan College—an Oakville, Ont., post-secondary school that may soon be considered one of the nation’s most sustainable higher education buildings.

Sheridan’s 12,077-m2 (130,000-sf) Skilled Trades Centre uses a 23,000-cfm dedicated outdoor air system (DOAS) ERV with molecular sieve desiccant enthalpy wheels to supply about 48,310-m2 (520,000-sf) of workshop and lab spaces. A second 19,000-cfm ERV uses hybrid system to supply active chilled beams in 20 classrooms.

The state-of-the-art building, which also uses light-emitting diodes (LEDs), rooftop photovoltaic (PV) systems, daylight harvesting, rainwater systems, and other sustainable technologies, will not be certified to LEED, even though its accumulated credits can qualify for Silver. While other universities target LEED ratings for new buildings to achieve annual energy intensities of 160 to 170 kWh/m2, the two ERVs are expected to help the Skilled Trades Centre reach a Sheridan-mandated energy intensity limit of 100kWh/m2 according to the school’s sustainable energy systems manager, Herbert Sinnock, CET/CEM, CMVP, LEED AP and project manager, Katherine Rinas.

The Skilled Trades Centre is part of a 30-year climate and energy master plan Sheridan created in 2012. The plan expects to reduce carbon emissions by 50 per cent and energy consumption costs by several million dollars by 2020. ERVs in the facility, as well as previous Sheridan projects, play an important role in the plan.

Another indication ERVs are here to stay in Canada is Sheridan’s plan of publicly promoting its two ventilators to cultivate public interest in the technology. Both ERV units are installed in a third-level mechanical room, fully visible from corridor passersby via a wall of glazing. A corridor-mounted LED dashboard from the building automation system (BAS) reflects real-time ERV statistical data and equipment operating diagrams.

Image courtesy Sheridan College

Sustainable equipment visibility does not stop there. The building will also host the campus’ new two-storey central plant mechanical room or ‘energy centre.’ Chillers, boilers, combined heat-power engines (CHP), and other essential central plant equipment supplies much of the campus, which is located in the Energy Centre’s glass enclosure, visible from the exterior and interior first- and second-floor corridors.

“The strategy at Sheridan College is to get people interested in sustainability and technology by showing it to them, rather than concealing it out of sight,” said Sinnock, who pointed out the centre is strategically located

between the engineering technology and skilled trades departments to draw potential synergy between the two academic programs.

Furthermore, putting the mechanical equipment in eyesight with potential accessible learning by students is an incentive to add HVAC/R and stationary engineering to a list of trade curriculums, already including electrical, plumbing, and welding.

“This building provides a platform for the college to roll into those programs where technologies such as ERVs can be studied,” said Sinnock.

In addition, Sheridan used the ERV technology to supplement six new rooftop direct-expansion (DX) HVAC systems in 2009. Two years later, the college constructed a building with a DOAS ERV and zone-based air tempering with heat pumps. In 2015, it replaced aged air-handling units (AHU) in one of its legacy buildings with a new system incorporating ERVs. In each case, the energy consumption was reduced because the ERVs were reclaiming the building’s heating and cooling.

Hospital designs

While Sheridan is a prime example of a university using ERVs, the technology is seen as nearly irreplaceable in new hospital HVAC designs to help comply with ASHRAE 170, Ventilation in Healthcare Facilities, as well as to reduce excessive humidity that nourish airborne biological contaminants.

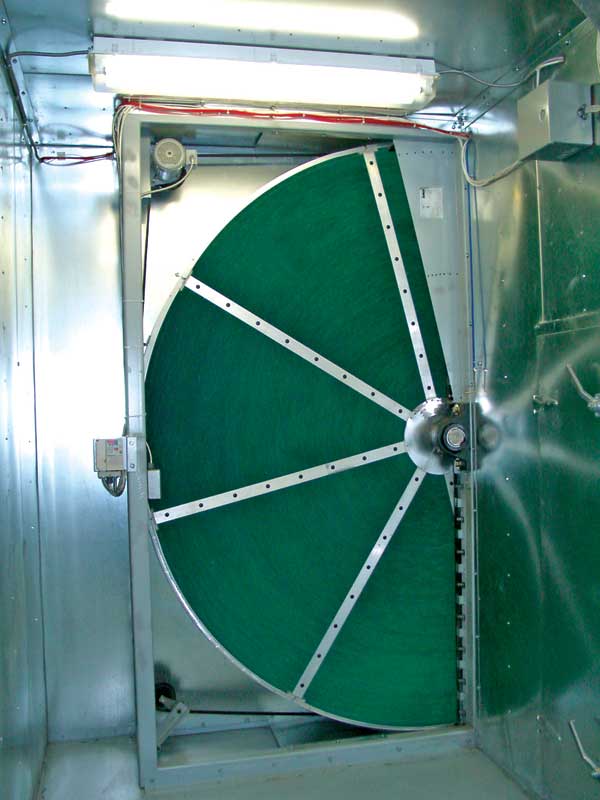

Image courtesy SEMCO LLC

Statistics surrounding hospital-acquired infections show a sense of emergency. One in every nine patients acquires HAI once entering a Canadian hospital, notes the Canadian Union of Public Employees (CUPE) on its website.

To offset the trend, many hospitals are looking to reduce 100 per cent outdoor air HVAC systems in an air replacement strategy. The entire air volume in a hospital can be replaced quickly by introducing 100 per cent outdoor air, and exhausting interior air along with any of its potential airborne contaminates.

Air replacement is a viable strategy, but it is cost-prohibitive to dehumidify heat or cool a huge volume of air surpassing 1 million cfms in larger facilities. Thus, facility engineers walk a tightrope when it comes to reducing operational HVAC energy costs while complying with ASHRAE 170.

Further, the challenge for hospital management is to maintain code-compliance, even though relative humidity (RH) levels can vary between spaces, such as a corridor, patient room, and surgery suite. Regardless of safe design precautions, such as controlling air changes and a room’s negative or positive pressurization, moisture will migrate from room to room, because of its affinity for drier spaces. Thus, controlling the RH in each space makes it easier to control the various vapour pressures and moisture migration into other spaces.

Desiccant specification choices in ERVs

Enthalpy wheels are ideal for heat recovery in many types of projects, but the wheel’s desiccant media choice—typically silica gel or molecular sieve material—is critical in hospitals for preventing the incoming outdoor air from residual contamination from the outgoing indoor air.

Silica gel has a propensity for cross-contamination because its pores can adsorb and then harbour contaminants from the exhaust air. This can also decrease latent heat transfer. Molecular sieve materials are not susceptible to contaminant adsorption, because the smaller pore size only allows the transfer of the water vapour from the exhaust to supply air streams.

In winter, when outdoor air is below 30 per cent RH due to HAI concerns, moisture collected from the exhaust air can be added to the supply air to raise indoor RH levels, it is critical to not affect outdoor air with indoor contaminants during the humidification process.

In order to further minimize cross-contamination, desiccant surfaces can be specified with anti-microbial coatings to help prevent airborne biological contaminants from harbouring in the media.

Specialty ERV concentration on surgery suites

Special ERV applications, such as the aforementioned hybrid system used for the Sheridan College workshops, are destined for hospitals requiring more extreme energy recovery and humidity reduction in critical areas. Surgery suites, for example, typically demand very low dewpoint temperatures of 5 C (42 F) and drier air, as per ASHRAE 170 requirements. The trend is to design operating rooms (ORs) with their own self-contained system to avoid contact with air from other parts of the hospital.

Standard enthalpy equipment typically cannot handle low dewpoints; however, the HVAC industry has recently developed alternative dehumidification strategies utilizing an active desiccant wheel to dry out the air to very low levels. These systems bring in outdoor air and use a cooling coil reducing the temperature to approximately 12 C (55 F), and then an active desiccant wheel takes the saturated cooling coil’s moisture and dehumidifies it by adding heat. The dried air leaves the wheel at about 26 C (80 F), but at –1 C (30 F) to 4 C (40 F) dewpoint temperatures. Then, the air can be fed to conventional air-handlers for the space’s sensible cooling. The systems deliver dry air on the ventilation portion only; removing the humidity from the space with just the outside air portion.

Another attribute is non-cross-contamination between the indoor and outdoor ventilation during heat recovery. The ventilation is only 20 to 30 per cent of the total air volume, so the challenging factor of moisture removal is easily handled.

Many hospitals are currently retrofitting their ORs’ HVAC systems to comply with ASHRAE 170’s requirements for humidity control. This may require either adding a DOAS to the OR’s air handler, or replacing the air-handler with a DOAS that performs dehumidification and controls space heating/cooling.

Conclusion

ERVs appear to have a strong upward curve as energy recovery becomes imperative for reaching codes, such as ASHRAE 90.1.

“We couldn’t imagine a new building on our campus without ERV,” said Sheridan’s Sinnock. “I see the future of Canadian green building as tempering at the zone level with methods such as chilled beams, heat pumps, or variable refrigerant flow. ERVs will play a major part in conditioning code-required outdoor air to complement those.”

The specified slider id does not exist.

Steve Ulm is the marketing director at SEMCO LLC, a Fläkt Woods Company specializing in energy recovery equipment, chilled beams, controlled chilled beam pump modules, spiral metal ductwork, and acoustical panel products. He has worked at SEMCO since 2015, and has over 20 years of experience in the component and industrial systems market. He holds a BSEE from Purdue University and an MBA from Northern Illinois University. He can be reached via e-mail at steve.ulm@flaktwoods.com[1].

Steve Ulm is the marketing director at SEMCO LLC, a Fläkt Woods Company specializing in energy recovery equipment, chilled beams, controlled chilled beam pump modules, spiral metal ductwork, and acoustical panel products. He has worked at SEMCO since 2015, and has over 20 years of experience in the component and industrial systems market. He holds a BSEE from Purdue University and an MBA from Northern Illinois University. He can be reached via e-mail at steve.ulm@flaktwoods.com[1].

- steve.ulm@flaktwoods.com: mailto:steve.ulm@flaktwoods.com

Source URL: https://www.constructioncanada.net/introducing-energy-recovery-ventilation/