Failures in plumbing pipe due to construction methods

by arslan_ahmed | December 23, 2022 9:00 am

[1]

[1]By Alan Humphreys PhD, P.E., and Phillip Sharff, P.E.

Metal corrosion is an ever-present problem in the plumbing industry. Common piping materials such as copper, steel, and cast-iron are readily oxidized and thus undergo aqueous corrosion at a rate dependent on the corrosivity of the service environment.

When properly designed and installed, plumbing systems will provide many decades of problem-free service. Careful corrosion engineering management, including attention to details such as materials selection, fluid mechanics, water-chemistry control, protective coatings, cathodic protection, and suitable material corrosion allowance, should ensure these materials comfortably survive their design life. However, actions during the construction or renovation of a building can have unintended consequences that can dramatically reduce the service life of plumbing systems.

This article highlights some recent plumbing pipe failures caused by actions during construction or renovation and discusses methods to avoid such problems.

Erosion-corrosion of copper pipe

[2]

[2]Seamless copper tubing conforming to ASTM B88, Standard Specification for Seamless Copper Water Tube,1 has been the most common material for small-diameter domestic water plumbing systems. This is because of its ease of installation, corrosion resistance, and competitive cost.

Clean copper surfaces are reactive with water, but oxide layers quickly form, which passivates the surface and retards further reaction. In addition, minerals in water can form insoluble scales such as carbonates, nitrates, and sulfates on tube interiors. This scale acts as a protective film to the copper surface, resulting in passivation of the pipe and a negligible rate of corrosion. The scaling potential of a water source is readily predicted from its chemistry, using indices such as the Langelier Saturation Index (LSI).

Mineral scale in copper tubing is chemically stable and under normal plumbing conditions would be expected to remain as a protective layer for the service life of the system. However, scale is mechanically weak and vulnerable to damage by turbulence due to high-water velocity or cavitation. This results in a sharp increase in the local corrosion rate where the protective scale has been removed—a mechanism known as erosion-corrosion. Canadian and American plumbing codes typically limit the velocity of water flow in copper tubing to 1.5 to 3 m (5 to 10 ft) per second to avoid erosion-corrosion, and a mechanical engineer will design a plumbing system using pipe diameters sufficient to respect these limits. Unfortunately, if renovation work is carried out on a building, the original plumbing design is not always available, and modifications to the plumbing system can possibly alter the flow rate.

[3]

[3]For example, the authors’ company recently worked on a project at a residential apartment building experiencing leaks in the domestic water system. This multi-storey building had a recirculating domestic hot water system to allow rapid on-demand hot water at all locations within the building. During a renovation project, it was necessary to change the location of the basement piping, so the return line of this recirculation loop was re-piped. Unfortunately, the plumber replaced this line with 12.7 mm (0.5 in.) diameter copper pipe, whereas the original pipe was 19 mm (0.75 in.) diameter. The diameter change reduced the cross-sectional area of the return line by 55 per cent, more than doubling fluid velocity, at a constant flow demand.

[4]

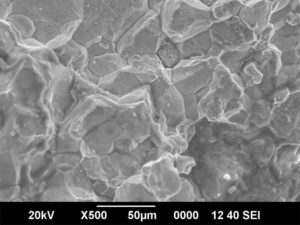

[4]As a result, leaks began to occur immediately downstream of bends in the pipe, which is where turbulence can be problematic at high fluid velocities. On sectioning the leaking pipe samples in their laboratory to inspect the interior condition, the authors’ company found the protective scale was eroded away at the leak location and observed horseshoe-shaped pits oriented in the direction of the water flow (See images 1 and 2). This internal condition is typical of erosion-corrosion.

The authors’ company advised the building owner to replace the 12.7 mm (0.5 in.) diameter return pipe with the original 19 mm (0.75 in.) size. This failure demonstrated it is unwise to conduct modifications to a plumbing system without engineering review.

Stress corrosion cracking of copper pipe

Copper is susceptible to a failure mechanism known as stress corrosion cracking, where a combination of tensile stress and corrosive liquid (e.g. ammonia) results in intergranular cracking of the copper microstructure. Flexible copper tubing is particularly susceptible to this mechanism. When flexible tubing coiled for packaging is uncoiled for installation, permanent stresses develop. If the tubing is exposed to a corrosive environment, premature failure due to stress corrosion cracking can occur.

[5]

[5]Flexible copper tubing conforming to ASTM B280, Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service,2 is used in HVAC systems for the transfer of a refrigerant, such as glycol, between a compressor and a heat exchanger. Although chilled copper lines typically develop an external corrosion patina due to condensation in a humid environment, no significant section loss occurs. However, copper tubing in a stressed state can fail if exposed to certain environments.

The authors’ company was engaged in a project where HVAC lines in a newly built apartment complex had developed leaks. During the construction of this wood-framed building, an extreme weather event had resulted in the wetting of the building’s interior frame. In the subsequent months, mould grew on these wood surfaces, leading to the implementation of a mould-abatement program. The manufacturer’s literature indicated the mould abatement chemicals were compatible with copper, so there should have been no corrosion issues. However, when the HVAC units were activated upon completion of the building, multiple leaks were discovered.

The HVAC lines in this building consisted of an uninsulated liquid line, bundled with a foam-insulated vapour line, held together at regular intervals by adhesive tape (See image 3 on page 39). A laboratory analysis determined discrete cracks had formed in the uninsulated liquid line at locations where the tape was present (See image 4). Metallographic and fractographic analysis confirmed the failure mechanism as stress corrosion cracking (See image 5). The authors’ company conducted experiments to demonstrate how the exposure of the tape and foam insulation to the mould-remediation chemicals resulted in the production of ammonium ions, which generated ammonia.

The HVAC copper lines in the building were replaced. This failure demonstrated caution should be used in spraying chemicals in a building containing plumbing piping, even if the data sheets suggest the materials are compatible. Temporarily wrapping exposed piping prior to spraying chemicals would be a prudent approach.

Internal corrosion of steel sprinkler pipe

[6]

[6]Wet fire suppression systems, consisting of steel piping conforming to ASTM A135, Standard Specification for Electric-Resistance-Welded Steel Pipe, are normally resistant to internal corrosion. This is because electrochemical corrosion reactions typically require oxygen, and dissolved oxygen in the water standing in sprinkler pipes is quickly consumed, and corrosion is suppressed. However, fire suppression piping exposed to potential freeze conditions requires the use of dry sprinkler systems, where the pipes are charged with compressed air rather than water.

Whereas wet sprinkler systems are filled with water and contain a finite amount of dissolved oxygen, dry sprinkler systems, which often contain inadvertent small quantities of water, can rapidly corrode, as there is an infinite amount of oxygen available for the electrochemical reaction. Standing water can collect in dry systems from the condensation of humid compressed air or from the accumulation of residual water from alarm testing. To combat this, fire codes such as National Fire Protection Association (NFPA) 13—Standard for the Installation of Sprinkler Systems—which is referenced by the National Fire Code of Canada (NFC), typically require dry sprinkler pipes to be sloped at a pitch of at least 6.3 mm (0.25 in.) per 3 m (10 ft) of pipe length towards a drain. An experienced mechanical contractor will know how to install a properly pitched dry sprinkler system.

[7]

[7]The authors’ company investigated a project where significant internal corrosion of a dry sprinkler system developed after only three years of service (See image 6 ). The sprinkler pipes were located in an unheated attic space, and it included ductwork for a HVAC system to be installed after the sprinkler pipes. When checking the sprinkler pipe pitch, they encountered local runs of pipe which were back-pitched, preventing water drainage and resulting in advanced corrosion. Upon further investigation, it was found that in order to accommodate duct installation, the pipe hangers were adjusted and the pipe position was altered, causing back-pitch of the sprinkler pipe at several locations (See image 7 ).

[8]

[8]The pitched pipe was incorrectly adjusted to install a nitrogen charging unit into the system. Nitrogen purges oxygen from pipes, thus preventing further corrosion. This is an instance of a contractor unknowingly affecting the performance of a system installed by another contractor with what appeared to be minor adjustments. Best practice is to make a final check of the sprinkler system after all components in the space are installed. It is also important for an engineer be involved at all stages of design and renovation.

Steel pipe in chilled water applications is susceptible to corrosion from surface condensation in a humid environment. Pipe insulation is used on chilled water pipe to minimize thermal transfer between the pipe and the ambient environment, and to inhibit condensation of water vapour on the pipe surface that can lead to accelerated corrosion of steel pipe—a mechanism known as corrosion under insulation (CUI).

[9]

[9]To prevent CUI, pipe insulation is installed with a moisture retarding cover, and insulation joints and seams must be carefully sealed with approved tape to form a competent vapour barrier that inhibits the intrusion of moisture-laden air to the pipe surface. Correctly installed insulation with an intact vapour barrier will protect chilled water pipe from CUI for many years of service (See image 8). Unfortunately, in their inspection of plumbing systems, the authors’ company frequently encounters pipe where the insulation vapour barrier has been compromised due to poor installation or damage from adjacent construction (See image 9), resulting in failures from CUI (See image 10).

Since plumbing pipe and other utilities are often installed in tight spaces, inadvertent damage during construction or renovations can occur. It is important that, when all construction is complete, insulated plumbing pipe is inspected to ensure the integrity of the insulation vapour barrier has not been compromised.

[10]

[10]Conclusion

Properly designed and installed plumbing pipe should not experience significant corrosion for the anticipated service life of the system. However, actions during the construction or renovation of a building can alter the environment of these systems, resulting in unanticipated and costly corrosion problems. Any construction activities that could impact a plumbing system should be properly assessed to preclude premature corrosion failure.

Notes

1 Refer to the Canadian Copper & Brass Development Association, visit http://en.coppercanada.ca/videos-publications/publications/pub28/pub28e-section1.html[11]

2 See note 1.

Authors

[12]lan Humphreys is a staff consultant and metallurgist in the engineering mechanics and infrastructure group at Simpson Gumpertz & Heger. He specializes in the failure analysis and structural assessment of materials systems which have degraded by mechanisms such as corrosion, fracture/fatigue, or wear. Humphreys can be reached at aohumphreys@sgh.com.

[12]lan Humphreys is a staff consultant and metallurgist in the engineering mechanics and infrastructure group at Simpson Gumpertz & Heger. He specializes in the failure analysis and structural assessment of materials systems which have degraded by mechanisms such as corrosion, fracture/fatigue, or wear. Humphreys can be reached at aohumphreys@sgh.com.

[13]Phillip Sharff is a principal at Simpson Gumpertz & Heger. He specializes in the performance of underground structures, piping systems, building and mechanical components, industrial structures, tanks, and structural materials. He has led many failure investigations of buried structures, building components, piping, and structural plastics materials, often involving forensic field studies, laboratory testing programs, structural analysis, and expert testimony. Sharff can be reached at pasharff@sgh.com.

[13]Phillip Sharff is a principal at Simpson Gumpertz & Heger. He specializes in the performance of underground structures, piping systems, building and mechanical components, industrial structures, tanks, and structural materials. He has led many failure investigations of buried structures, building components, piping, and structural plastics materials, often involving forensic field studies, laboratory testing programs, structural analysis, and expert testimony. Sharff can be reached at pasharff@sgh.com.

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PHOTO11.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PHOTO21.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/Photo-3-Insulated-Vapor-Line-and-Exposed-Line-Connected-by-Adhesive-Tape.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/Photo-4-Crack-in-Pipe-at-Location-of-Adhesive.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PHOTO51.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PHOTO61.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PHOTO71.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/Photo-8-Properly-Installed-Pipe-Insulation-with-Taped-Seams-and-Joints-to-Provide-Competant-Vapor-Barrier.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/Photo-9-Mechanically-Damaged-Insulation-on-Chilled-Water-Pipe.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/Photo-10-CUI-on-Chilled-Water-Pipes.jpg

- http://en.coppercanada.ca/videos-publications/publications/pub28/pub28e-section1.html: http://en.coppercanada.ca/videos-publications/publications/pub28/pub28e-section1.html

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/AHumphreys_F.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2022/12/PSharff_F.jpg

Source URL: https://www.constructioncanada.net/failures-in-plumbing-pipe-due-to-construction-methods/